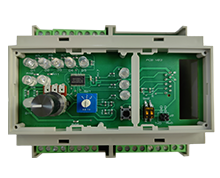

Free Sample/10pcs

$25 only/10pcs

$15/pc

100% New and Origianl

The company provides SMT patch processing, post-soldering, DIP (wave soldering) assembly and one-stop OEM and material services. As a top electronic PCB one-stop manufacturing service provider, PCB patch processing is an integral part of us. The company focuses on PCB prototype, small batch, and batch business. The company has more than 2,000 square meters of standard factory buildings. Introduced 4 SMT Yamaha high-speed patch lines, automatic solder paste printing machine, solder paste detection, reflow soldering, AOI, first article tester, etc., and equipped with wave soldering, dry ice plate washer and other equipment. We continuously optimize our production management system. Improve quality and help customers save project time and costs,

Products are widely used in industrial control, medical equipment, smart home, military industry and other fields. We can assemble (including 01005 packages, BGA, QFN and other packages), through-hole assembly, hybrid assembly, soft-hard board assembly and final products, screw shells and other assemblies. The production process complies with IPC-A-600E standards. Customers are all over the world, and they are well received. The rate is as high as 99%

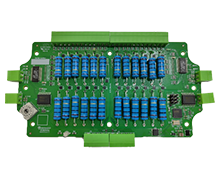

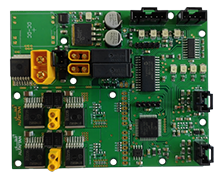

MBS Control PCB

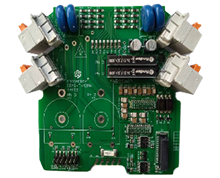

LoRa IoT PCBA

Vessel Control PCB

HVAC Control PCB

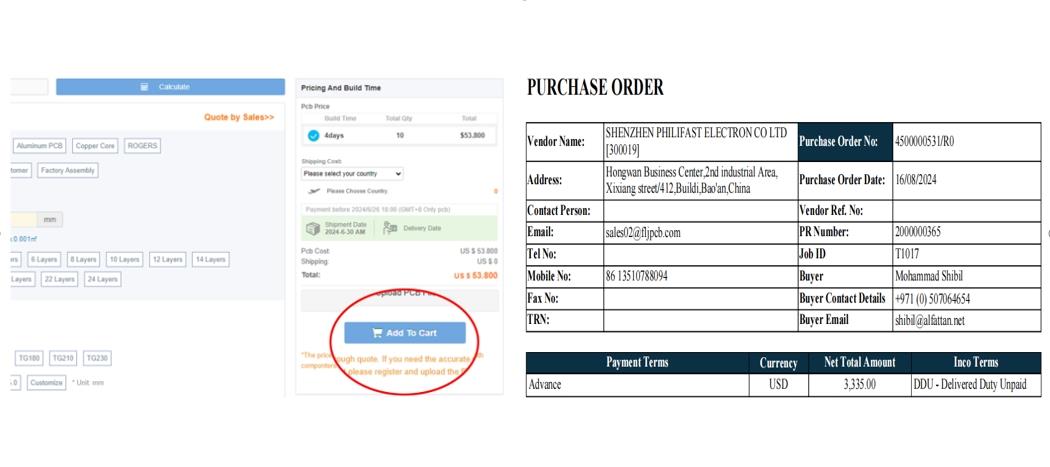

Order Proposal: right after we receive your orders,our sales representive will collect and check all files and requirements including pcb spec.,bom files,assembly requests...,and share it to our purchase and engineer team to ensure they can fully understand and arrange their work correctly.

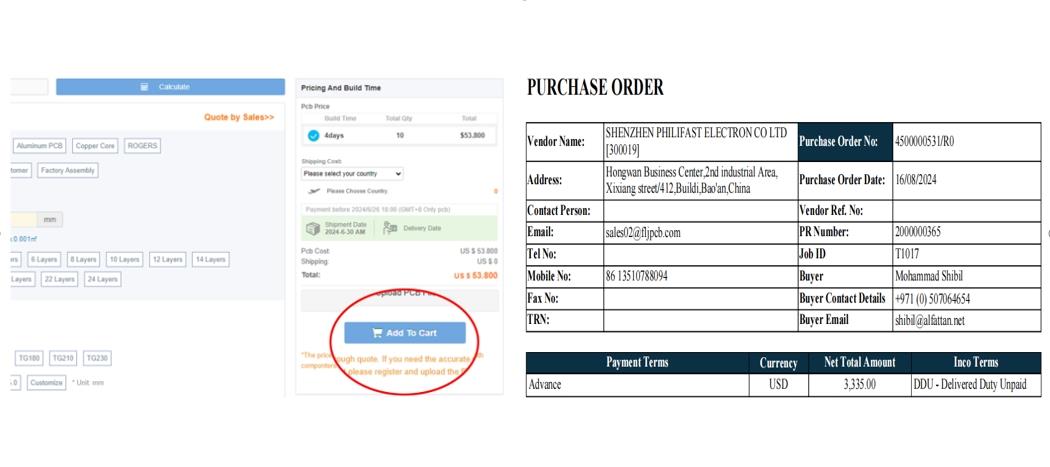

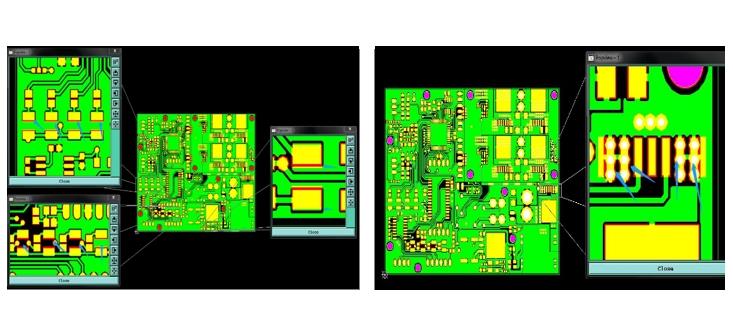

EQ&Files confirming: To eliminate circuit issues and misunderstanding of design files, our pcb engineers will check the Gerber data and PCB requirements before production

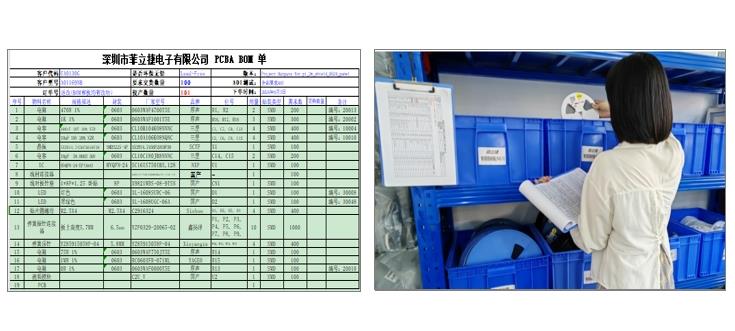

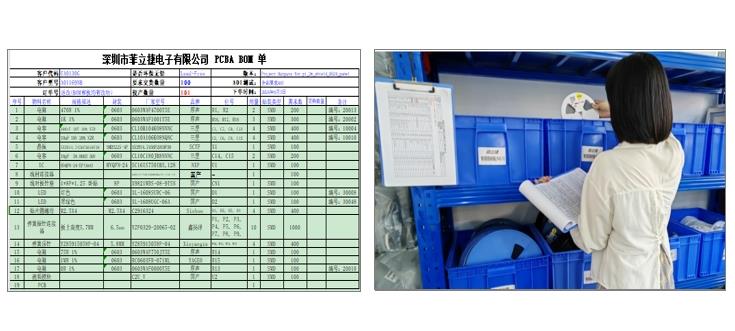

Our bom engineers will also check BOM to see if there’s any doubts or issues for the parts

Material preparation:once all production requirements and work files are confirmed,we will arrange the production of bare PCBs and PCB stencil,at the same time,our purchase department will buy all components as per BOM files to ensure all material to arrive in time.

IQC Inspection: Check all received components, including incoming material quantity, component specifications,polarity, model, and compare them one by one with PCB designations and pads to see if the component packaging is consistent with the pad packaging. If there is any problem, it will be Instant feedback to purchasing for material change

SMD soldering:We focus on each details from solder brashing and checking,temperature control of reflow oven,AOI,QC check during SMD mounting,we inspect pcba by visual, AOI, X-ray, visual inspection is for basic checking, AOI is for solder paste,missing parts,polarity checking,X-ray is for BGA/QFN checking

DIP soldering:First samples photoes for check to avoid the issues,for mass production,mass order for wave soldering,small batch by manual.

Dry ice blasting:all boards would be cleaned by dry ice cleaner.which won’t damage the parts and ensure PCBA clean.

We also help our clients to do firmware programming and functional tests.which is the best way to test if boards can work or not,if it’s failed to program and test,we will analize why the issue happens,defective pcba can be repaired before packing to reduce the loss of both.

Packing: Antistatic bag+bubble+Standard export carton, customized package is allowed.

Shipping: For small volume goods are usually shipped by DHL,FeDex,UPS,TNT...,For mass volume PCBA, we ship by air or sea,customer can also choose their own forwarder to delivery.

Order Proposal: right after we receive your orders,our sales representive will collect and check all files and requirements including pcb spec.,bom files,assembly requests...,and share it to our purchase and engineer team to ensure they can fully understand and arrange their work correctly.

EQ&Files confirming: To eliminate circuit issues and misunderstanding of design files, our pcb engineers will check the Gerber data and PCB requirements before production

Our bom engineers will also check BOM to see if there’s any doubts or issues for the parts

Material preparation:once all production requirements and work files are confirmed,we will arrange the production of bare PCBs and PCB stencil,at the same time,our purchase department will buy all components as per BOM files to ensure all material to arrive in time.

IQC Inspection: Check all received components, including incoming material quantity, component specifications,polarity, model, and compare them one by one with PCB designations and pads to see if the component packaging is consistent with the pad packaging. If there is any problem, it will be Instant feedback to purchasing for material change

SMD soldering:We focus on each details from solder brashing and checking,temperature control of reflow oven,AOI,QC check during SMD mounting,we inspect pcba by visual, AOI, X-ray, visual inspection is for basic checking, AOI is for solder paste,missing parts,polarity checking,X-ray is for BGA/QFN checking

DIP soldering:First samples photoes for check to avoid the issues,for mass production,mass order for wave soldering,small batch by manual.

Dry ice blasting:all boards would be cleaned by dry ice cleaner.which won’t damage the parts and ensure PCBA clean.

We also help our clients to do firmware programming and functional tests.which is the best way to test if boards can work or not,if it’s failed to program and test,we will analize why the issue happens,defective pcba can be repaired before packing to reduce the loss of both.

Packing: Antistatic bag+bubble+Standard export carton, customized package is allowed.

Shipping: For small volume goods are usually shipped by DHL,FeDex,UPS,TNT...,For mass volume PCBA, we ship by air or sea,customer can also choose their own forwarder to delivery.

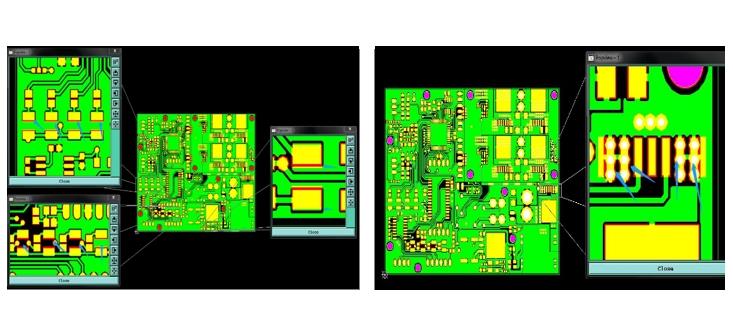

Testing Procedures

*Visual Inspection

*AOI Inspection

*Firmware Programming

*Function Test