Template for PCB&PCB Assembly Files.

We receive a lot of inquiry documents every day, during the process of reviewing the PCB files, we found that some of the files are incomplete. which will not only delay the production progress due to later confirmation and update of the information, but also cause production problems.

To ensure customers to provide accurate production files,PCBASail provides templates for customer reference

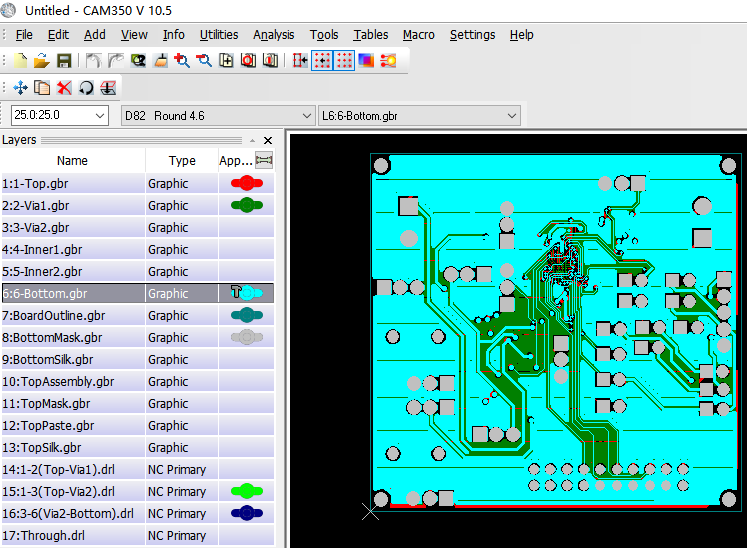

PCB files(Take the gerber file as an example)

We can accept PCB files in many formats (.pcb, .pcbdoc, .brd, .cam,Gerber),while Gerber files(RS-274X format) are always applied for production as a default.which covers the data of every layers,you can open it by CAM350 tool for final files confirmation before production.

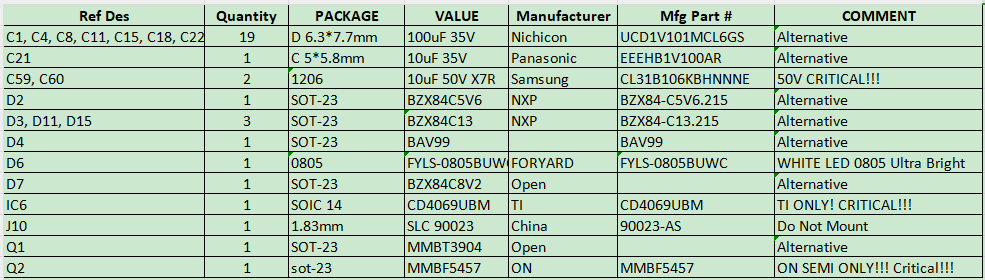

Bill of Materials (.xls .csv .xlsx)

A complete and clear BOM is crucial for the production of PCBA. Each electronic component must be uniquely determined. Once the wrong materials are used due to unclear BOM information, it will directly cause the PCB board to not work properly. So what detailed information is necessary for the components,

1) Reference Designators(“refdes”):Each component has a reference number,which is necessary for assembly

2) Quantity:The usage quantity of each different component per board

3) Package:It describes the parts size specification

4) Value:especially for resistors and capacitors,value is very important if there’s no full part number.

5) Manufacturer: it speculates the brand of the parts would be used,if there’s no requirements for brand,you can note:”open” or “alternative”

6) Part number(“Mfg Part”):the part number must be unique and common

7) Comments:for any other requirements,you can note it draw our attention.

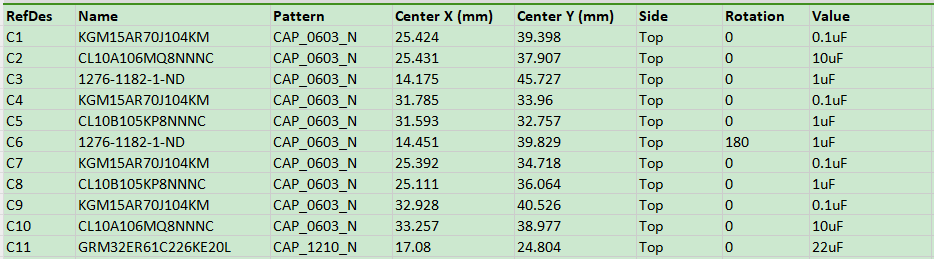

Pick&Place File(.xls .csv .xlsx .txt)

Pick&Place files(Centroid file) will help us to target the position of the each components,our technician sets coordinate program for SMT machine so that they can

pick up the parts and place it into the target position accurately

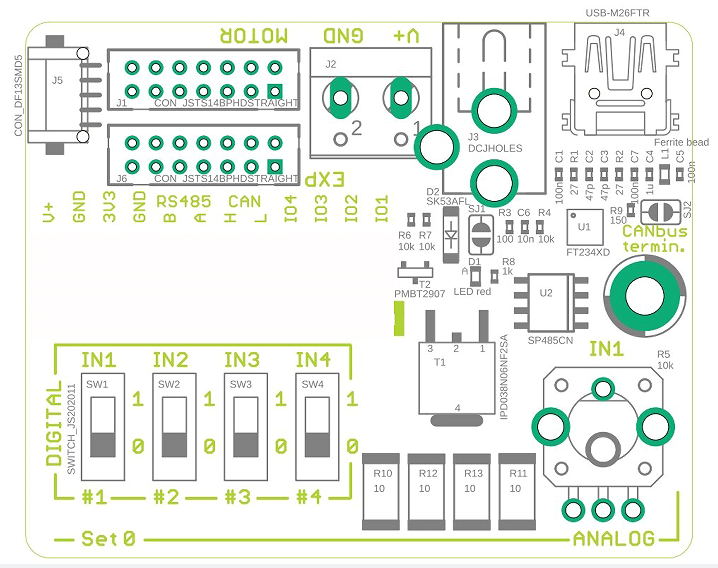

Assembly Drawing:

Assembly Drawing can help us quickly find the location of each component and determine the polarity of the component, which plays a very important role in our quality QC.

If you still have any doubts with PCB files for production,please contact PCBASAIL via [email protected]