PCB Capabilities

PCBA Capabilities

How PCBASAIL Handle Your PCBA Orders Step-By-Step

Compared with PCB manufacturing, the PCB assembly process is relatively simple. The following content is to allow customers to intuitively understand our entire process from PCBA ordering to production and shipment, from PCB manufacturing, BOM component procurement, SMT/THT assembly, and burning. From testing to the final shipment of finished products, PCBASAIL focuses on controlling every process detail, constantly optimizing production technology and costs, and becoming the most trustworthy EMS processing factory for customers.

-

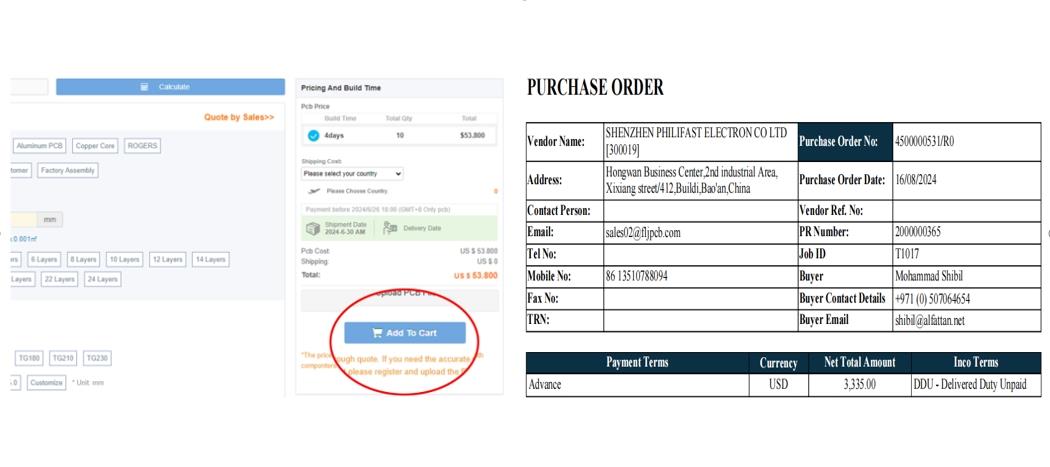

Order Requests

Order Proposal: right after we receive your orders,our sales representive will collect and check all files and requirements including pcb spec.,bom files,assembly requests...,and share it to our purchase and engineer team to ensure they can fully understand and arrange their work correctly.

-

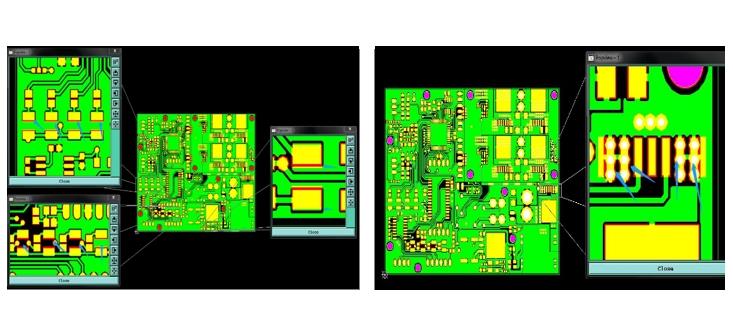

Engineering Check Before production

EQ&Files confirming: To eliminate circuit issues and misunderstanding of design files, our pcb engineers will check the Gerber data and PCB requirements before production

Our bom engineers will also check BOM to see if there’s any doubts or issues for the parts

-

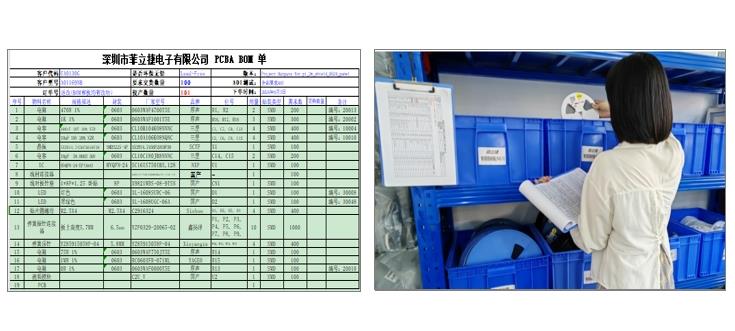

Material Preparation

Material preparation:once all production requirements and work files are confirmed,we will arrange the production of bare PCBs and PCB stencil,at the same time,our purchase department will buy all components as per BOM files to ensure all material to arrive in time.

-

Incoming inspection

IQC Inspection: Check all received components, including incoming material quantity, component specifications,polarity, model, and compare them one by one with PCB designations and pads to see if the component packaging is consistent with the pad packaging. If there is any problem, it will be Instant feedback to purchasing for material change

-

SMT assembly

SMD soldering:We focus on each details from solder brashing and checking,temperature control of reflow oven,AOI,QC check during SMD mounting,we inspect pcba by visual, AOI, X-ray, visual inspection is for basic checking, AOI is for solder paste,missing parts,polarity checking,X-ray is for BGA/QFN checking

-

Wave soldering&Dry ice blasting

DIP soldering:First samples photoes for check to avoid the issues,for mass production,mass order for wave soldering,small batch by manual.

Dry ice blasting:all boards would be cleaned by dry ice cleaner.which won’t damage the parts and ensure PCBA clean.

-

Programming&function tests

We also help our clients to do firmware programming and functional tests.which is the best way to test if boards can work or not,if it’s failed to program and test,we will analize why the issue happens,defective pcba can be repaired before packing to reduce the loss of both.

-

Packing and Shipping

Packing: Antistatic bag+bubble+Standard export carton, customized package is allowed.

Shipping: For small volume goods are usually shipped by DHL,FeDex,UPS,TNT...,For mass volume PCBA, we ship by air or sea,customer can also choose their own forwarder to delivery.

PCBASAIL always provides the best purchasing experience and service, taking customer service as its core and pursuing quality.For more of our quality control,you can read the page of Quality Control,welcome to your inquires.