High-Density Interconnect PCBs

What is a High-Density Interconnect (HDI) PCB?

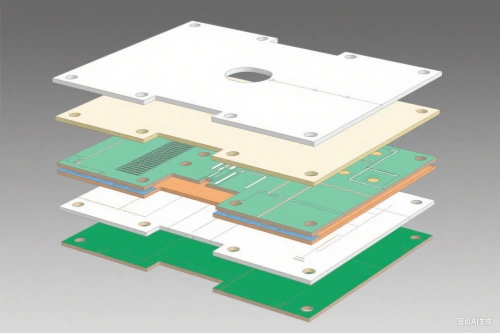

High-Density Interconnect (HDI) PCBs are a type of printed circuit board (technology) characterized by high circuit density, produced using microvias and buried vias technology. With the continuous development of technology and increasing electrical requirements for high-speed signals, circuit boards must provide impedance control with AC characteristics, high-frequency transmission capabilities, and reduced unnecessary radiation (EMI). Adopting Stripline and Microstrip structures, multi-layering has become a necessary design. To mitigate signal transmission quality issues, insulating materials with low dielectric constants and low attenuation rates are used. Meanwhile, to accommodate the miniaturization and array packaging of electronic components, circuit boards are constantly increasing in density to meet demand.

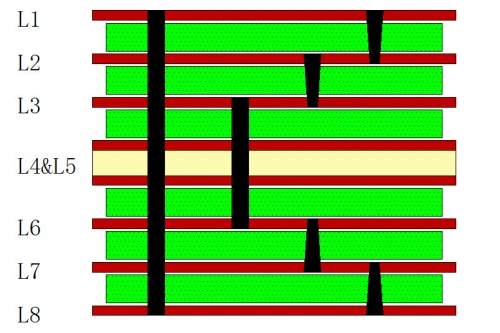

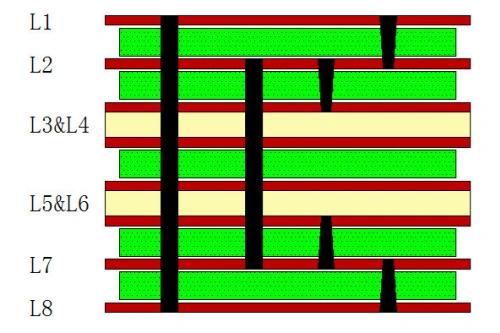

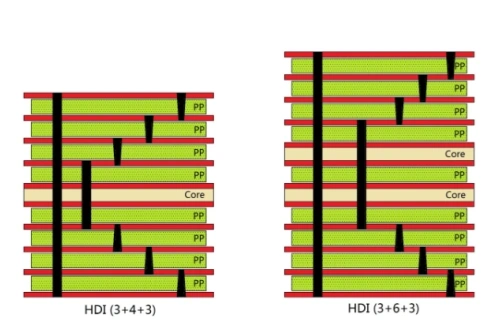

Layer Stack Structures of HDI PCBs

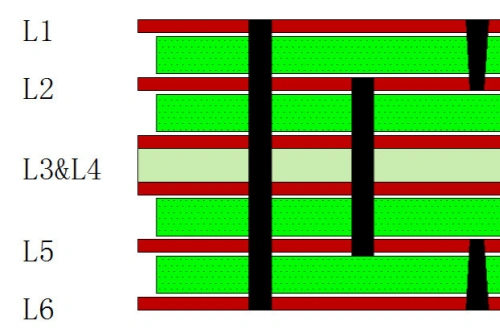

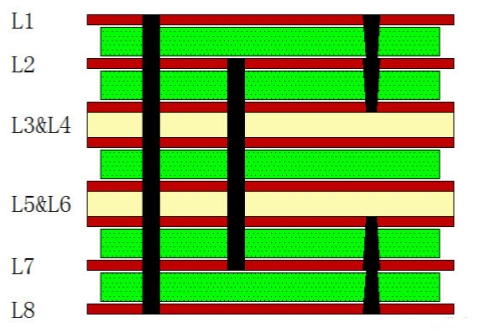

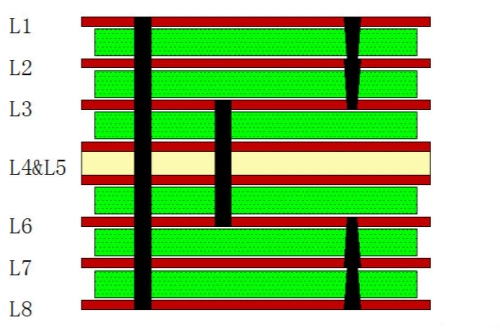

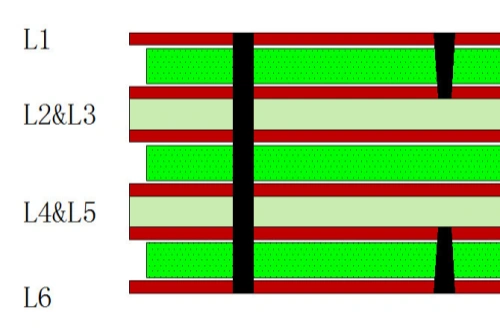

Simple Single-Build-Up Printed Boards

These are the simplest boards, with no buried vias in the inner multi-layer board, completed in a single lamination. Though they are single-build-up boards, their manufacturing is quite similar to the single lamination of conventional multi-layer boards. The key difference is that subsequent processes (such as laser drilling of blind vias) are required. Since this stack structure has no buried vias, it can be fabricated by using a core for layers 2 and 3, another core for layers 4 and 5, adding dielectric layers and copper foils to the outer layers, and completing all in one lamination. This simplicity makes their cost lower than conventional single-build-up boards.

Why Use HDI PCBs?

Compared to surface-mount technology (SMT) and through-hole boards, HDI PCBs offer numerous technical advantages:

Design flexibility

HDI boards provide greater design flexibility than SMT or through-hole boards. Designers can leverage high component density, facilitating faster signal processing.

Space efficiency

Thanks to advanced technical features, HDI boards easily accommodate more connections in fewer layers on the same board.

Reliability

HDI boards have smaller vias, and their low aspect ratio (AR) makes them more reliable than through-hole vias.

Suitability for dense packaging

HDI is ideal for dense, complex packaging involving high pin counts and small pitches.

Compact PCB demand

HDI boards address the increasing need for smaller PCBs. Multiple PCBs can be integrated into a single HDI board.

Signal integrity

The advanced technical features of HDI PCBs enhance signal integrity and electrical performance, making them preferred over SMT or through-hole boards.

What to Consider When Designing HDI PCBs?

Like any PCB technology, HDI PCBs require specific considerations:

Materials

While materials are a consideration in all PCB manufacturing, HDI PCBs demand careful selection due to manufacturing constraints. The electrical performance of signal traces depends on the chosen material type, which is also a key cost-determining factor.

Every Layer Interconnection (ELIC)

This technology is now used in smartphone construction, helping reduce mechanical holes and achieve smaller pitches within the board.

Trace uniformity and minimum line width

These are critical to avoiding short circuits or disconnections.

Component placement

HDI technology emphasizes precise component positioning, which ensures the feasibility of board installation, soldering, and maintenance.

Distribution of blind and buried vias

Asymmetric stack designs may create unnecessary stress, leading to board warpage.

Expertise

Before sending PCBs to manufacturers, factors such as layer count, high-density component placement, and manufacturing complexity must be considered. Any design issues encountered during manufacturing can be costly, potentially requiring full redesigns or scrapping.

Increasing design complexity, demands for precision, and the growing relevance of compact PCBs are among the factors shifting focus to the planning, layout, and manufacturing of HDI PCBs.

Need HDI PCB Solutions?

We provide custom HDI PCB manufacturing services tailored to your specific design requirements. Contact us for expert support.

Request a Quote