What Is ENIG? PCB Immersion Gold Process Explained

12 Jun 2025 15:18:31 GMT

PCBASAIL

12 Jun 2025 15:18:31 GMT

PCBASAIL

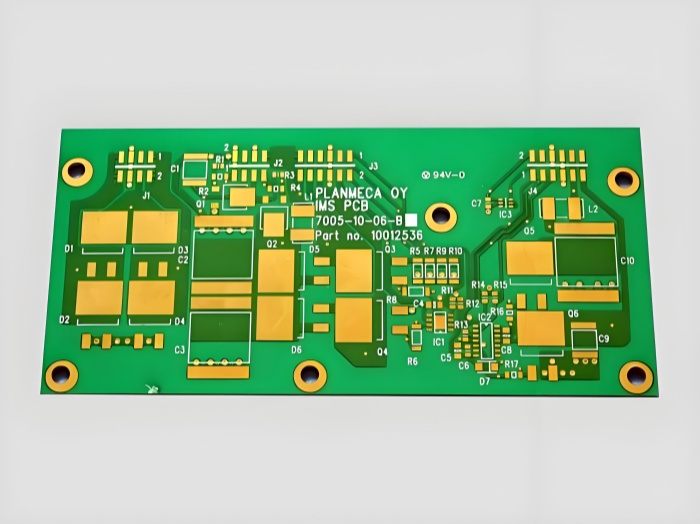

What Is Immersion Gold (ENIG)?

Copper on a circuit board is primarily electrolytic (pure) copper, which readily oxidizes in air. Oxidation degrades conductivity—leading to poor solder wetting or contact failures—and thus reduces PCB performance. To prevent this, copper pads receive a surface finish. Immersion gold (ENIG) deposits a thin gold layer on the copper. Gold effectively isolates copper from air and prevents oxidation, so ENIG is an anti‑oxidation treatment that chemically covers the copper with gold. It is also called “chemical gold.”

PCB ENIG Process Flow

1. Process Overview

The ENIG process aims to deposit a bright, smooth, solderable nickel‑gold plating on the PCB surface. It consists of four main stages:

Pre‑treatment (degreasing, micro‑etch, activation, post‑immersion rinse)

Nickel plating

Gold plating

Post‑treatment (waste‑gold rinse, DI water rinse, drying)

2. Pre‑treatment

Typical pre‑treatment steps are:

Degreasing (30 % AD‑482)

Micro‑etch (60 g/L APS, 2 % H₂SO₄)

Activation (10 % Act‑354‑2)

Post‑immersion (1 % H₂SO₄)

These steps remove copper oxides and deposit palladium on the copper to activate the surface for nickel plating. Any lapse here will compromise subsequent nickel and gold deposition and may cause batch rejects. Process baths must be regularly analyzed and replenished within specified ranges. For example, micro‑etch rate should be 25 μ–40 μ; activation solution must be replaced once copper content exceeds 800 ppm. Weekly tank changes and cleanings of the degreasing, micro‑etch, activation, and rinse baths are critical to maintain PCB quality.

3. Nickel Plating

Electroless nickel plating requires strict control of bath composition and operating conditions. The bath should be analyzed twice per shift, and nickel reducer replenished based on board copper area or experience. Additives must be dosed in small, distributed increments to avoid local over‑reaction and accelerated aging. Bath temperature strongly affects nickel thickness—maintain 85 °C–90 °C—and pH should be 5.3–5.7. When not in production, lower the bath to ~70 °C to slow aging. Electroless nickel is sensitive to impurities; inhibitors include low‑melting heavy metals (Pb, Sn, Hg, Ti, Bi).

4. Gold Plating

Immersion gold is a displacement (immersion) process. A typical gold bath contains 1.5–3.5 g/L Au and 0.06–0.16 mol/L complexing agent. The bath operates at pH 4–5 and 85 °C–90 °C, producing a smooth, fine‑crystal gold layer by displacing pure gold onto the nickel‑phosphorus surface.

5. Post‑treatment

Post‑treatment steps include:

Waste‑gold rinse

DI water rinse

Drying

If available, a horizontal spray‑rinse system further cleans the board:

Chemical spray (10 % H₂SO₄ + 30 g/L H₂O₂)

High‑pressure DI rinse (30–50 psi)

Final DI rinse

Blow‑dry and bake

This sequence thoroughly removes residual chemicals and moisture from holes and surfaces, yielding a uniformly bright ENIG finish.

How to Choose Between ENIG and Gold Fingers

What Are Gold Fingers?

Gold fingers are the brass contact pads on memory modules or edge connectors. They consist of multiple gold‑plated conductive pads arranged like fingers. All signals between the module and socket transmit through these “fingers.”

Choosing ENIG vs. Gold Fingers

ENIG Advantages:

Stable, bright, smooth plating

Excellent solderability

Typical thickness: 1–3 μin

Four‑stage process (pre‑treat, nickel, gold, post‑treat)

Cost Considerations:

ENIG is more expensive than HASL (hot‑air solder leveling). If gold thickness exceeds standard fab limits, costs rise further. However, if your design demands high solderability or electrical performance—such as edge connectors (gold fingers) or fine line‑space boards—ENIG (plus gold fingers) ensures reliable solder joints, stable performance, and robust resistance to shock or wear.Hybrid Approach:

For boards with gold‑finger edges but ample trace‑to‑pad spacing elsewhere, you can specify HASL for the main board and ENIG only on the fingers. This reduces cost while maintaining edge‑connector reliability. If trace‑pad spacing is tight, HASL may cause solder bridging and short circuits, and gold fingers suffer from insertion wear and contact failures.

Select the fabrication process that balances cost control with board performance and reliability.

ENIG vs. HASL Process Differences

ENIG:

Chemical redox process yields a thick, soft, gold‑colored layer.

Ideal for high‑density, high‑end applications.

HASL (Hot‑Air Solder Leveling):

Applies and levels a solder (tin‑lead or lead‑free) layer with hot‑air knives.

Most common, low cost, but less planar.

Key Differences:

Solderability: HASL has solder already on the pads, making manual soldering very easy; ENIG also offers excellent solderability.

Signal Integrity: ENIG pads bond solder mask and copper more firmly; signals travel in the copper layer with minimal skin‑effect impact.

Shelf Life: ENIG resists “black pad” and oxidation, so boards have longer shelf life; HASL boards oxidize faster.

Planarity: ENIG is extremely flat; HASL struggles to produce fine, planar pads, complicating SMT placement.

ENIG vs. Other Surface Finishes

| Surface Finish | Solderability | Cost | Oxidation Resistance | Typical Use Case |

|---|---|---|---|---|

| ENIG | Excellent | High | Excellent | High-density assemblies, high-end devices |

| HASL | Good | Low | Moderate | General electronics |

| OSP | Good | Low | Moderate | Eco-friendly consumer electronics |

| Immersion Silver | Excellent | Medium | Moderate | High-frequency signal products |

Typical Applications of ENIG PCBs

Communications

5G Base Stations: High conductivity and oxidation resistance ensure stable, low‑loss signal transmission in harsh outdoor environments; dual‑sided ENIG increases solder yield and extends lifetime.

Microwave/RF Modules: ENIG meets strict high‑frequency transmission requirements in satellite ground stations and microwave links.

Fiber‑Optic Transceivers: Critical electro‑optical conversion modules rely on ENIG’s electrical stability and corrosion resistance.

Medical Equipment

Patient Monitors (ECG, glucose meters): ENIG’s precision conductivity and stability enable accurate, low‑level bio‑signal capture; corrosion resistance endures frequent sterilization.

Imaging Systems (CT, MRI): High‑speed data processing boards require ENIG for reliable, long‑term performance and reduced imaging errors.

Aerospace & Defense

Avionics: ENIG withstands extreme temperatures, vibration, and corrosion, ensuring flight‑control and navigation electronics remain reliable.

Satellite Electronics: In space, ENIG resists cosmic radiation and thermal cycling, preserving signal integrity and connector reliability.

Industrial Control

Automation Controllers: Harsh factory environments demand ENIG’s corrosion resistance and electrical stability for sensors and PLCs.

Smart Monitoring Systems: Real‑time data transmission systems benefit from ENIG’s high‑speed performance and long‑term reliability, reducing maintenance costs.

Consumer Electronics

Smartphones & Tablets: ENIG improves signal integrity and corrosion resistance in thin, high‑performance boards exposed to moisture.

Wearables: Compact modules require ENIG for efficient signal transmission and reliable micro‑component soldering.