How To Start PCB Manufacturing And Assembly Business?

11 Apr 2025 15:10:05 GMT

PCBASAIL

11 Apr 2025 15:10:05 GMT

PCBASAIL

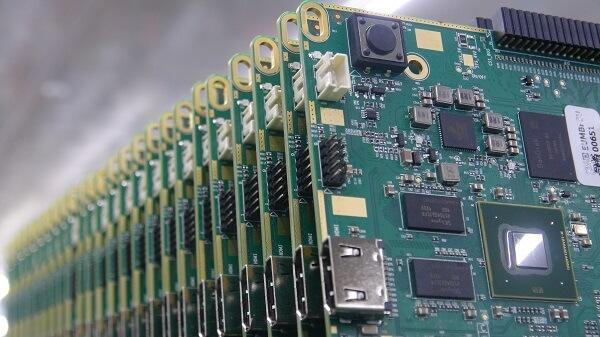

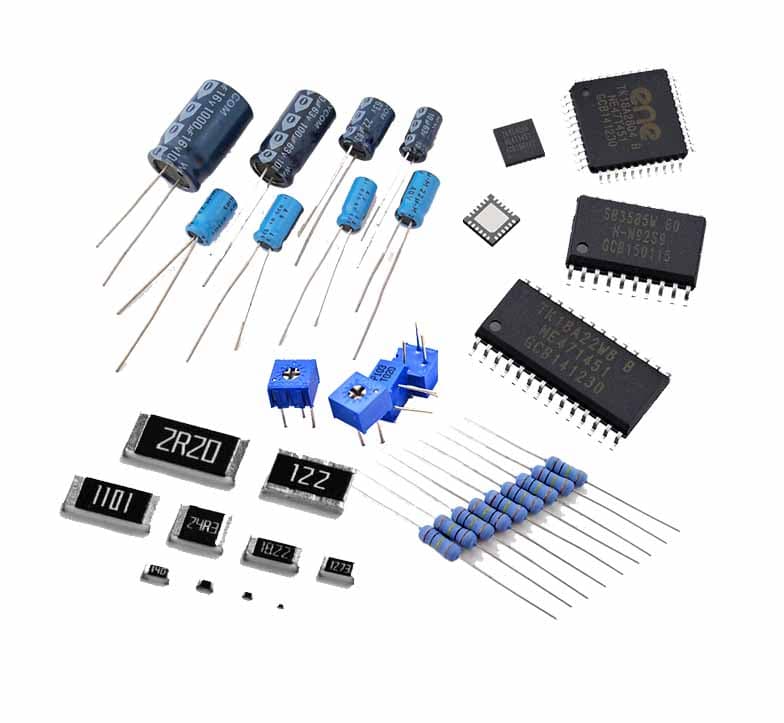

Printed circuit boards (PCBs) provide component assembly and electrical connections for various electronic devices. Components mainly include resistors, capacitors, diodes, triodes, chips, transformers and other electronic components, as well as various connectors, plugs and other components for electrical connections. As the core carrier of electronic equipment signal transmission, signal reception and power supply, circuit boards have been widely used in consumer electronics, industrial control, medical equipment, artificial intelligence and other fields.It brings new opportunities for entrepreneurs engaged in PCB manufacturing and assembly business

1,Steps for starting PCB manufacturing and assembly business?

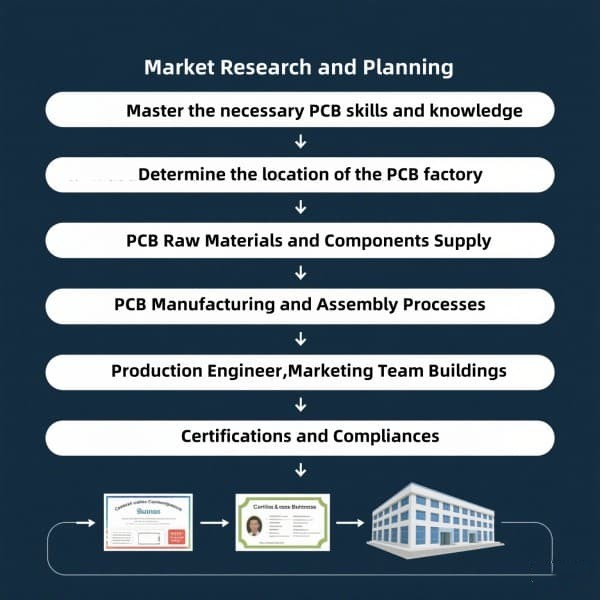

1)Market Research and Planning

Learn about the trends, target markets and competition in the electronic PCB manufacturing and assembly industry through the Internet or field visits. And the demand for PCB manufacturing and assembly services in your region and even around the world. Combined with your own strengths, clarify your company size, business scope, target customers, and pricing standards.

2) Master the necessary PCB skills and knowledge

Be familiar with PCB industry standards, environmental protection requirements, and local laws and regulations. Understand the expertise of PCB design, manufacturing and assembly processes by hiring professional engineers and management teams.

3) Determine the location of the PCB factory

Combining factors such as transportation, cost, customer groups, etc. Choose a suitable location for your factory and introduce the equipment required for PCB manufacturing and assembly, such as lithography machines, etching equipment, drilling machines, SMT equipment, and testing equipment.

4) PCB Raw Materials and Components Supply

Find suitable suppliers of PCB materials (such as copper clad laminates, solder mask, screen printing inks), electronic components and assembly materials. Establish a reliable supply chain.

5) PCB Manufacturing and Assembly Processes

Develop and create detailed workflows, including PCB manufacturing and assembly processes, and set up a comprehensive quality control system,Strict quality control measures are implemented throughout the manufacturing and assembly process. This includes inspecting raw materials, monitoring production steps, and testing the electrical performance and reliability of finished PCBs. Advanced test equipment such as ICT testers and flying probe testers to ensure high-quality and efficient PCB output.

6) Production Engineer,Marketing Team Buildings

Build a skilled workforce, including PCB designers, production management and technicians. Provide a comprehensive training program to ensure that production can be carried out safely and efficiently.and build an elite sales team and develop marketing strategies to promote your PCB manufacturing and assembly services to gain more customer orders.

7) Certifications and Compliances

It is necessary to obtain all certifications and compliance certificates required by the target market and industry standards. This includes ISO certification, UL certification and other certifications.

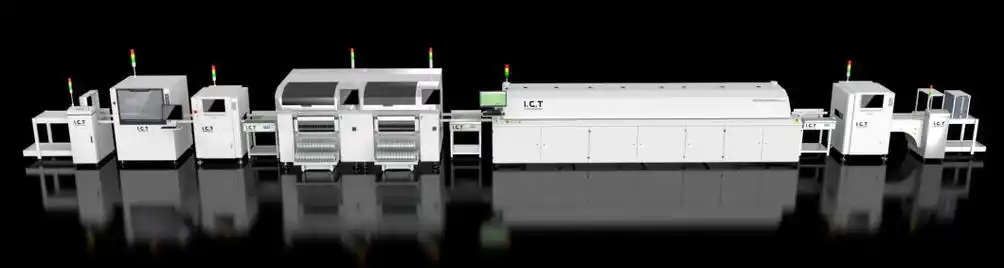

2,Which main machines required to start PCB manufacturing and assembly business?

1)PCB Manufacturing

Photoplotter

Etching Machine

Drilling MachinePlating

Equipment

2)PCB Assembly

SMT Machine:Pick and place SMD parts on the boards

Reflow Oven:Solid SMD parts on the boards

Wave Soldering Machine:Soldering THT parts automaticly

Inspection Machine:SPI,AOI,FAI,X-Ray Machine

In addition to these main machines, other equipment such as solder paste printers, component feeders, and various testing and measurement tools are also essential for a complete PCB manufacturing and assembly line. The specific machines and their configurations may vary depending on the complexity and volume of the PCB production.

3,What materials we need to prepare for PCB manufacturing and assembly business?

Materials for PCB Manufacturing

· Substrate materials: The most commonly used substrate material is copper clad laminate (CCL), which consists of a non-conductive substrate (glass fiber epoxy resin (FR-4)) and copper foil. Of course, for products with different applications, we need to use different boards. For example, for high-frequency applications, we also need ceramic materials such as Rogers boards.

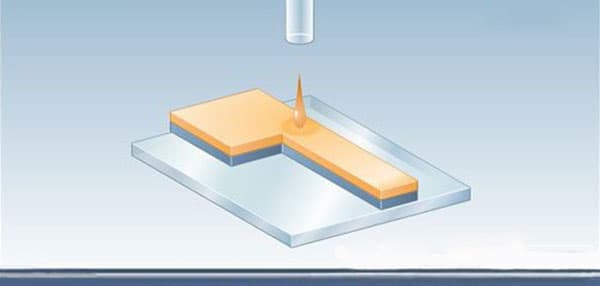

· Photoresist materials: Photoresist is a light - sensitive material used in the imaging process. There are two types: positive photoresist, where the exposed areas are dissolved during development, and negative photoresist, where the unexposed areas are dissolved. It is applied to the copper - clad laminate and then exposed to ultraviolet light through a photomask to transfer the circuit pattern.

· Etching and plating chemicals: For the etching process, chemicals such as ferric chloride, hydrochloric acid, and hydrogen peroxide are used to remove the unwanted copper from the CCL. In the plating process, solutions of copper sulfate, nickel sulfate, and gold chloride are used to deposit metal layers on the PCB surface to improve conductivity and corrosion resistance.

· Drilling consumables: Drill bits are essential for creating holes in the PCB. They come in various sizes and types, depending on the hole diameter and the material of the PCB. Additionally, drilling lubricants and coolants are used to reduce heat and wear during the drilling process.

Materials for PCB Assembly

· Electronic components: we need to purchase a wide variety of components for pcb assembly such as resistors, capacitors, inductors, diodes, transistors, integrated circuits (ICs), and connectors. These components suppliers need to be carefully selected to ensure all components are original and new.

· Solder materials: Solder paste and solder wire are indispensable materials for PCB assembly. Solder paste is mainly used for SMT patches, which is a mixture of solder powder, flux and other additives. Solder wire is used for through-hole (THT) welding. For precision component patches, we need to use high-quality solder paste, such as Alpha and Qianzhu solder paste. Considering environmental protection requirements, all materials need to be lead-free.

· Flux materials: Flux plays an important role in the soldering process and is helpful in promoting good solderability of solder. There are many types of flux, such as rosin-based flux, soluble flux and no-clean flux, each of which has its own characteristics and application requirements.

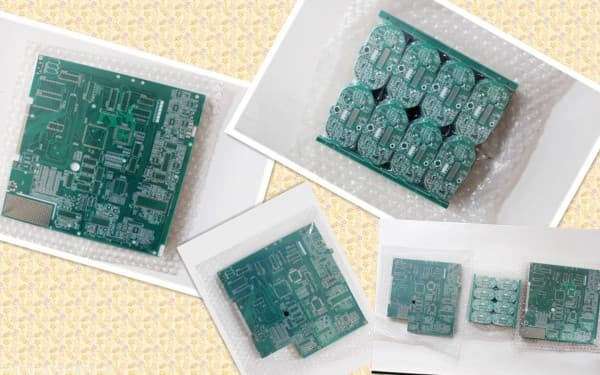

· Packaging materials: After the PCB is assembled, we need to package the PCB for protection and transportation. Commonly used packaging materials include plastic bags, bubble wrap, cartons and anti-static packaging to prevent electrostatic discharge from damaging electronic components.

Which services involved to start PCB manufacturing and assembly business:

PCB layout Design

PCB Clone

PCB Manufacturing

Components Sourcing

PCB Assembly

Box Housing

Product assembly

IC Programming

Functional Test

In short, while developing PCB manufacturing and assembly business brings huge opportunities, it also faces many challenges, such as huge capital investment (equipment, raw materials, factory buildings, etc.), high technical barriers (design, process, new technology follow-up), strict quality control (standards and regulations, testing and traceability), fierce market competition (global competition, diverse demands, market saturation) and complex compliance requirements (environmental protection, hazardous substance control, energy saving and consumption reduction) and many other challenges.