How PCB Reverse Engineering Works: Step-by-Step Guide

10 Jun 2025 13:39:58 GMT

PCBASAIL

10 Jun 2025 13:39:58 GMT

PCBASAIL

The Technical Implementation Process of PCB Reverse Engineering (Cloning)

In simple terms, PCB reverse engineering starts with scanning the circuit board to be cloned, recording the detailed positions of all components. These components are then removed and listed into a bill of materials (BOM) for procurement. The bare board is scanned into images, which are then processed with reverse engineering software to recreate the PCB layout file. This file is sent to a board manufacturer for fabrication. Once the board is made, the purchased components are soldered back onto the new PCB, followed by testing and debugging.

I. Detailed Steps of PCB Reverse Engineering

Initial Inspection and Recording

Once you have the PCB, first record all component models, parameters, and locations on paper, especially paying attention to the orientation of diodes, transistors, and IC notches. It’s best to take high-resolution photos of the component layout. Modern PCBs often have tiny components that can be easily overlooked.Component Removal and Board Cleaning

Remove all components from the board, and desolder the pads. Clean the PCB with alcohol, then scan it at high resolution to obtain clear images. Lightly sand the top and bottom layers with fine sandpaper until the copper shines. Then scan both sides again using Photoshop in color mode. Ensure the board is placed flat and straight in the scanner for usable images.Image Processing

Adjust the contrast and brightness to clearly distinguish copper traces from non-copper areas. Convert the image to black and white and save it as BMP files (TOP.BMP and BOT.BMP). If necessary, use Photoshop to correct and repair any defects in the image.Image Conversion to CAD Files

Convert the BMP files into Protel format files. Load both layers into Protel. If the pads and vias align correctly, the previous steps were successful. If there are discrepancies, repeat step 3. Precision is crucial, as even small errors can affect the final quality and compatibility.Tracing and Component Placement

Convert the TOP BMP to a Protel PCB file (TOP.PCB), placing the graphics in the SILK layer (yellow). Trace the circuit in the TOP layer and place the components according to your reference from step 2. Once completed, delete the SILK layer and repeat for other layers until all are drawn.Layer Merging

Import both TOP.PCB and BOT.PCB into Protel and merge them into a single file.Printing and Verification

Use a laser printer to print the top and bottom layers onto transparent films (at 1:1 scale). Overlay the films onto the original PCB to verify alignment. If everything matches, you’ve successfully cloned the board. However, this is only half the job — you still need to test the cloned board to verify that its electronic performance matches the original.

Note: For multilayer boards, internal layers must also be sanded and repeated through steps 3–5. File naming should correspond to each layer. Double-sided boards are significantly easier to clone than multilayer ones, which are prone to alignment issues. Special care is required to handle plated through holes (PTH) and non-plated through holes (NPTH).

II. Double-Layer PCB Cloning Method

Scan both the top and bottom layers of the PCB and save them as BMP files.

Open QuickPCB 2005, click “File > Open Background Image” to load the top scan. Use

PAGEUPto zoom,PPto place a pad,PTto trace lines — it’s like a digital “tracing” activity. Save the project as a.B2Pfile.Load the bottom layer scan as a new background image.

Open the previously saved

.B2Pfile. You’ll see the traced layout overlaid. Use “Options > Layer Settings” to hide the top layer and silkscreen, leaving only the vias.Now align the vias on the bottom image and trace the bottom layout. Save the

.B2Pagain — it now includes both layers.Export the file as a PCB layout. You can now modify, generate schematics, or directly send it for manufacturing.

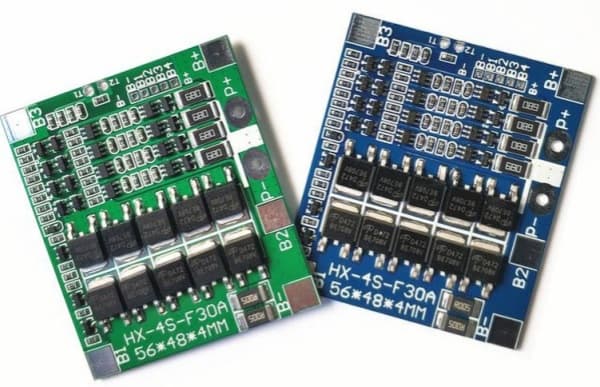

III. Multilayer PCB Cloning

Cloning a 4-layer board involves repeating the process for two double-sided boards. A 6-layer board requires three, and so on. The real challenge with multilayer boards is that internal traces are hidden.

To reveal the inner layers, layer separation is required. This can be done with chemicals, mechanical peeling, or — most effectively and safely — with sandpaper.

After finishing the top and bottom layers, use sandpaper to gradually grind off the top to expose the inner layers. Use regular sandpaper from a hardware store. Place the board flat and rub evenly. Silkscreen and solder mask are easy to remove; copper traces need more effort. Smaller boards take a few minutes, while complex ones like memory sticks may take 10+ minutes. Strength and patience help here.

Grinding is currently the most widely used and economical method for inner layer separation. Try it on a discarded PCB first — it’s not technically difficult, just time-consuming and physical.

PCB Layout Design Review

After laying out the system, review the PCB design for optimization. Key considerations:

Signal and Power Routing

Is the layout optimal and feasible for routing? Are signal paths, power, and ground networks well planned?Dimensional Accuracy

Are board dimensions accurate? Do they meet manufacturing requirements and mechanical fitting, including connector positions?Component Clearance

Ensure no spatial conflicts in both 2D and 3D, especially component height. For wave-soldering, component height should generally not exceed 3mm.Component Density and Arrangement

Is the component layout balanced and tidy? Are all components placed? Consider both signal flow and spatial density.Ease of Maintenance

Frequently replaced parts should be accessible, and plug-in boards should be easily inserted and removed.