Complete Guide to PCB Cleaning Processes and Technologies

05 Jun 2025 16:59:55 GMT

PCBASAIL

05 Jun 2025 16:59:55 GMT

PCBASAIL

1.1 Water-based cleaning process

The water-based cleaning process uses water as the cleaning medium. To enhance the cleaning effect, a small amount of chemical substances such as surfactants, detergent aids, and corrosion inhibitors (generally 2%–10%) can be added to the water. And according to the specific conditions of different types of pollution → Depending on the specific types of contaminants on the printed circuit board (PCB), additives can be incorporated into the water-based cleaning agent to expand its application range. Water-based cleaning agents have a good dissolving effect on water-soluble dirt. Combined with physical cleaning methods such as heating, brushing, spraying, and ultrasonic cleaning, better cleaning effects can be achieved. Adding surfactants to water-based cleaning agents can greatly reduce the surface tension of water, enhance the penetration and spreading ability of water-based cleaning agents, and better penetrate into the gaps between closely arranged electronic components, and remove the dirt that has penetrated into the substrate of the printed circuit board.

The residues of synthetic active solder flux can also be removed well by using the dissolving effect of water and the emulsifying and dispersing effect of surfactants. Not only can various water-soluble dirt be dissolved and removed, but also insoluble dirt such as synthetic resins and fats can be removed.For cleaning PCBs using rosin-based flux, adding appropriate saponifiers is necessary. Saponifiers are chemicals that react with organic acids (e.g., rosin acid in rosin) and fatty acids in grease to form water-soluble fatty acid salts (soaps). This is a common ingredient in many cleaning agents used to clean flux and grease on printed circuit boards. Saponifiers are usually alkaline inorganic substances such as strong bases such as sodium hydroxide and potassium hydroxide, or they may be alkaline organic substances such as monoethanolamine. Commercial saponifiers generally also contain organic solvents and surfactant components to clean and remove residues that cannot undergo saponification reactions. Since saponifiers may corrode metals such as aluminum and zinc on printed circuit boards, especially when the cleaning temperature is relatively high and the cleaning time is relatively long, it is easy to aggravate the corrosion. Therefore, corrosion inhibitors should be added to the formula. However, it should be noted that printed circuit boards with components that are sensitive to alkaline substances should not be cleaned with water-based cleaning agents containing saponifiers.

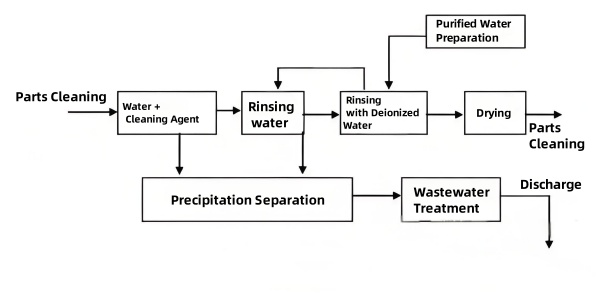

In the process of water-based cleaning, if ultrasonic cleaning is used in combination, the "cavitation effect" of a large number of microscopic air bubbles generated during the propagation of ultrasonic waves in the cleaning liquid can effectively remove insoluble dirt from the electronic circuit board. Considering the compatibility requirements of PCBs, electronic components, and ultrasonic waves, the ultrasonic frequency used for PCB cleaning is typically around 40 KHz. The water-based cleaning process includes three steps: cleaning, rinsing, and drying. First, the printed circuit boards are batch cleaned with a water-based cleaning agent with a concentration of 2%-10% in combination with physical cleaning methods such as heating, brushing, spraying, and ultrasonic cleaning, and then rinsed with pure water or deionized water (DI water) 2-3 times, and finally dried with hot air. The need to use pure water for rinsing in water-based cleaning is the reason why the cost of water-based cleaning is very high. Although high-quality water quality is a reliable guarantee of cleaning quality, in some cases, using low-cost deionized water with a conductivity of 5 μS·cm for rinsing first, and finally using high-purity deionized water with a conductivity of 18um·cm for rinsing can also achieve good cleaning results. The typical water cleaning process is shown in Figure 1. A typical process is: batch cleaning of electronic circuit boards with water-based cleaning agents at a temperature of 55°C, and strong jet cleaning for 5 minutes, then rinsing with deionized water at 55°C for 15 minutes, and finally drying with hot air at 60°C for 20 minutes. In order to improve the utilization rate of water resources, tap water used in the cleaning process or deionized water used in the rinsing tank, according to the literature, using tap water (hard water containing more ions) in pre-cleaning can not only greatly reduce production costs, but also its decontamination ability is not worse than soft water or deionized water.

Four cleaning technologies for printed circuit boards and the main factors that should be considered. Detailed information

2. Semi-aqueous cleaning

2.1 Semi-aqueous cleaning agents

The components of semi-aqueous cleaning agents generally contain organic solvents and surfactants. For example, the EC-7 semi-aqueous cleaning agent, which was first used in the cleaning of printed circuit boards, is composed of terpene hydrocarbon solvents and surfactants. Most semi-aqueous cleaning agents contain water in their formulas, but because the water content is low (only 5%–20%), semi-aqueous solvents remain transparent and uniform solutions like solvent-based cleaning agents. Unlike general solvent cleaning agents, semi-aqueous cleaning agents use organic solvents with a relatively high boiling point, so they are less volatile and do not need to be cleaned in a closed environment like solvent cleaning agents. In addition, during the cleaning process, the cleaning agent does not need to be frequently replaced, only the cleaning agent dosage needs to be appropriately supplemented. The organic solvents used to prepare semi-aqueous cleaning agents for cleaning printed circuit boards mainly include terpenes and petroleum hydrocarbon solvents, glycol ethers, N-methylpyrrolidone, etc. When selecting the type of solvent, it should be based on the pollution of raw materials such as printed circuit boards and electronic components, as well as the type of solder used during welding.

2.2 The semi-aqueous cleaning process

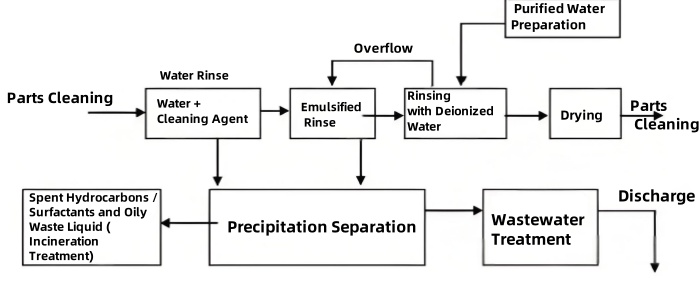

It also includes three steps: cleaning, rinsing and drying. The cleaning process is often combined with ultrasonic cleaning to improve the cleaning effect and reduce the cleaning time. Since the use of ultrasonic waves will increase the temperature of the cleaning agent, it is necessary to strictly control the cleaning temperature and it must not exceed the flash point of the cleaning solution (generally the cleaning temperature is controlled below 70°C). An emulsification recovery tank is added between the cleaning and rinsing processes. The concentration of organic solvents in the semi-aqueous cleaning liquid is very high. After cleaning, there will still be a lot of cleaning liquid on the surface of the printed circuit board. If the cleaned printed circuit board is directly placed in the water rinsing liquid, the organic solvent on the surface of the printed circuit board will pollute the rinsing water, greatly increasing the load of the subsequent water treatment process. By adding an emulsification recovery device containing an emulsifier water solvent between the cleaning and rinsing processes, the organic solvent on the surface of the printed circuit board can be stripped from the surface of the printed circuit board by emulsification dispersion. In this emulsification recovery device, the organic solvent and dirt precipitation can be separated and recovered by using a filter and an oil-water separation device. Since there is very little organic solvent on the surface of the printed circuit board entering the rinsing tank, the load of the rinsing process and the load of wastewater treatment are reduced. Rinse with deionized water 2-3 times to remove the dirt. Since semi-aqueous cleaning uses water as a rinsing agent, there is the same drying problem as water-based cleaning, and similar multiple measures need to be adopted to increase the drying speed.

2.3 Advantages and Disadvantages of Semi-aqueous Cleaning Process

The advantages of semi-aqueous cleaning process are: it is highly adaptable to various welding processes, so the original welding process does not need to be changed when using semi-aqueous cleaning process; it has strong cleaning ability and can remove water-soluble dirt and oil at the same time; it has good compatibility with most metal and plastic materials, and is not easy to volatilize compared with solvent cleaning agents, and the evaporation loss during use is small. The disadvantages are: it has the same problems as water-based cleaning, such as the need to use pure water for rinsing, difficult drying, and large amount of wastewater treatment. The semi-aqueous cleaning process requires a large site and space, and the one-time investment in equipment is large, especially for online cleaning machines. Since semi-aqueous cleaning agents contain more organic solvents, it is necessary to increase safety measures such as protection against toxic solvents, fire prevention and explosion prevention. Moreover, semi-aqueous cleaning agents cannot be recycled and reused by distillation like solvent cleaning agents, so the cost is relatively high. See Figure 2

Detailed information on the four cleaning technologies for printed circuit boards and the main factors that should be considered

Figure 2 Typical semi-aqueous cleaning process flow

3. Solvent cleaning process

3.1 Organic solvents used for cleaning printed circuit boards

The use of organic solvents to clean printed circuit boards is to utilize their dissolving effect on dirt. After phasing out ODS (ozone-depleting substance) cleaning agents such as CFC-113 and TCA, the currently used solvent-based cleaning agents are mainly fluorine-based solvents like HCFC, HFC, and HFE. In addition, hydrocarbon solvents and alcohol solvents can also be used. In order to improve the cleaning effect of fluorine-based solvents, hydrocarbon solvents, alcohol solvents, etc. are also added to form mixed solvents. Some mixed solvents are azeotropic mixtures with constant boiling points (such as azeotropic mixture solvent cleaning agents made of HCFC-141b-141b and methanol, HCFC-225 and ethanol). Since these fluorine-based solvents also have the advantage of being non-flammable and their performance is very similar to that of CFC-113, the cleaning process and cleaning equipment basically do not need to be changed or only need to be slightly adjusted.

3.2 Advantages and Disadvantages of Solvent Cleaning

The solvent cleaning process is relatively simple. It only needs to use the same solvent cleaning agent for cleaning and rinsing. Since the volatility of solvent cleaning agents is generally very good, no special drying process is required. After use, the solvent can be separated from the dirt by distillation and recycled, which not only reduces the cost, but also makes waste liquid treatment relatively simple. The cleaning equipment originally cleaned with CFC-113 can be used without major modifications; solvent cleaning is particularly suitable for cleaning printed circuit boards that are sensitive to water and have poor component sealing. The disadvantages of various alternative solvent cleaning agents have been introduced above and will not be repeated.

3.3 Typical solvent cleaning process

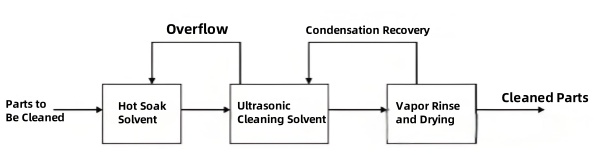

Typical solvent cleaning processes include the following: Ultrasonic plus immersion cleaning - spray cleaning - gas phase rinsing and drying Solvent heating immersion cleaning - cold rinsing - spray cleaning - gas phase rinsing and drying Gas phase cleaning - ultrasonic plus immersion cleaning - cold rinsing - gas phase rinsing and drying Gas phase cleaning - spray cleaning - gas phase rinsing and drying See Figure 3

Four cleaning technologies for printed circuit boards and the main factors that should be considered. Detailed information

Figure 3 Typical solvent cleaning process flow

4. No-clean process

4.1 What is the no-clean process

The no-clean process refers to quality control and process control of raw materials such as PCBs and electronic components. This alternative process is characterized by low conversion costs, low production and operation costs, and environmental friendliness.For enterprises with high automation, large production scale, and low requirements for post-weld product reliability performance indicators, it is most suitable to switch to the no-clean process. In addition, the use of the no-clean process saves the cost of cleaning equipment, cleaning agents, etc., which can greatly reduce operating costs.

4.2 Key issues to be addressed when using the no-clean process

The following three key factors should be fully considered when selecting the no-clean process: evaluation of the selection of flux/solder paste used; adjustment and control of the production process; quality control of raw materials.

4.2.1 Selection and evaluation of flux/solder paste used

The selection and evaluation of flux/solder paste is the primary task to be solved in the development and implementation of the no-clean process. It is necessary to ensure that the residue of flux/solder paste after welding will not affect the reliability performance index of electronic products. Practice has proved that weak organic acid flux with low solid content and rosin flux with medium and low activity and low residue can meet the requirements of the reliability performance index of electronic products. RMA type rosin flux with low activity and residue can be used for printed circuit boards of general electronic products. This type of flux has no special requirements for the welding environment, but it should be noted that its residue after welding is still relatively large, so it is not suitable for circuit boards with three-proof coating or surface mounting. Circuit boards that need to be treated with three anti-corrosion layers or other surface protection treatments should use low-solid content weak organic acid type flux, because this type of flux has less residue after soldering and has the least effect on the adhesion between the surface coating and the circuit board. However, most of these fluxes have poor anti-oxidation effect on circuit boards and components during the preheating process, so the welding process should be carried out under nitrogen protection when using this type of flux. Taking nitrogen protection measures can not only prevent the oxidation of circuit boards and components during the preheating process, but also improve the wetting performance of welding, reduce the formation of solder balls, and improve the welding quality.

4.2.2 Adjustment and control of production process

Due to the use of no-clean flux/solder paste, the welding process and process parameters will inevitably change, including increasing the use of nitrogen as a protective gas, adjusting the temperature change curve, changing the flux coating method (using spray coating), strengthening the monitoring of flux and lead-tin solder components, changing the installation method of electronic components, and the transmission and installation method of printed circuit boards. For example, the transmission and installation of electronic components and printed circuit boards can be replaced by mechanized automatic transmission and installation instead of manual operation, thus avoiding the adverse effects of hand sweat and fingerprints on the reliability of printed circuit boards. The activity of the flux can be adjusted to the best state just before welding by adjusting the temperature curve in the wave soldering machine and the reflow soldering machine, thereby improving the quality of the soldering. In addition, as mentioned earlier, for printed circuit boards with high reliability requirements, when using weak organic acid type flux with low solid content, nitrogen protection should also be used during welding. Spray-type flux is used and the amount of flux applied is strictly controlled. The amount of flux applied can be reduced as much as possible while ensuring the quality of welding, so that the residual amount of flux after welding can be kept at the lowest level. For printed circuit boards with relatively high requirements for welding reliability, the control of process parameters must be more stringent. For example, the temperature curve in the wave soldering machine and the reflow soldering machine must be measured before production to meet the process requirements. The chemical composition of the lead-tin solder must be analyzed at least once, and it must be replaced immediately if it is found to be unsatisfactory. When the flux is foamed, the flux should be monitored in real time. After the cleaning-free process is completed, the cleaning-free solder wire must be used for re-welding and repair. Only by adopting an effective production process can the use of cleaning-free flux/solder achieve good welding results.

4.2.3 Quality control of raw materials

The high quality requirements for various raw materials are an important factor affecting the cleaning-free process. Therefore, when using the cleaning-free process, the quality of various raw materials must be strictly controlled. For example, the cleanliness level and solderability of printed circuit boards and electronic components, the quality and stability of flux/solder, the quality of surface protection materials, the effectiveness of process control and quality management, etc. are controlled. Because any unqualified link in the production process will lead to unqualified final products.

5. Main factors to be considered in selecting alternative technologies

When choosing which alternative technologies to use, there are many factors to consider, and they are often mutually restrictive. Therefore, you should start from your specific actual situation and consider comprehensively to find the most suitable alternative technology. The factors that should be considered are mainly the following:

5.1 The situation of electronic products

That is, consider the importance of electronic products and their requirements for cleaning quality: Generally speaking, the higher the importance of electronic products, the higher the requirements for cleaning quality. For example, electronic products used in artificial satellites, aerospace instruments, submarine telecommunications, military equipment, and medical equipment involving life require extremely high reliability, while the reliability requirements for daily necessities and general industrial products are much lower. The environment in which electronic products are used also has a great relationship. For example, electronic products that are often in relatively harsh environments such as high temperature and high humidity must be strictly cleaned, and their ion contamination and surface insulation resistance after cleaning must be strictly controlled. For electronic equipment used on warships and ships used in marine environments, surface treatment should also be performed.According to the ANSI/J-STD-001B standard, electronic products are classified into three levels.Among them, the third category of electronic products must be cleaned and their cleanliness must be strictly controlled. Their ion contamination and surface insulation resistance should be tested batch by batch, while the first category of electronic products can be exempted from cleaning, and their cleanliness should be tested regularly.

Relationship, such as electronic products that are often in harsh environments such as high temperature and high humidity must be strictly cleaned, and their ion contamination and surface insulation resistance after cleaning must be strictly controlled. For electronic equipment used in warships and ships in marine environments, surface treatment should also be performed. According to my country's ANSI/J-STD-001B standard, electronic products are divided into three levels. Among them, the third category of electronic products must be cleaned and their cleanliness must be strictly controlled. Their ion contamination and surface insulation resistance should be tested batch by batch, while the first category of electronic products can be exempted from cleaning, and their cleanliness should be tested regularly. See Table 1

| Category | Definition & Scope | Cleaning Process | Cleanliness Standard |

|---|---|---|---|

| Class III | High-reliability electronic products (e.g., military, aerospace, medical equipment) | Washing with solvents, semi-aqueous cleaning agents, or water-based cleaning agents; must use high-purity water for final rinse; soft drying required | Level I Residual contaminants: ≤1.0 μg/cm² NaCl equivalent |

| Class II | Durable electronic products (e.g., industrial control equipment that works in non-harsh environments) | Washing with solvents, semi-aqueous cleaning agents, or water-based cleaning agents; soft drying required if necessary | Level II Residual contaminants: 1.5–10 μg/cm² NaCl equivalent |

| Class I | General electronic products (e.g., office equipment) | Normally not cleaned | Level III Residual contaminants: >10 μg/cm² NaCl equivalent |

Four cleaning technologies for printed circuit boards and main factors that should be considered for details

Table 1 Classification of electronic products and their cleanliness levels

5.2 Types of flux used

The amount of flux remaining on the printed circuit board is different when different welding processes are used, and the corresponding cleaning processes and cleaning agents are also different. Using a flux with high chemical activity, the reliability of welding is also high, but the corrosion of the flux residue after welding is also high. A cleaning process and cleaning agent with good cleaning effect must be used to completely remove the residue. On the contrary, the soldering reliability is also lower when using a soldering flux with lower chemical activity or lower solid content, but the soldering flux residue after soldering is less corrosive and can be cleaned by general methods or even without cleaning. See Table 2

| Type of Flux | Recommended Cleaning Method |

|---|---|

| Rosin Flux (RS) | Solvent cleaning, saponification cleaning |

| Low Residue Flux (R, RMA, RA, RSA) | Solvent cleaning, semi-aqueous cleaning, water-based cleaning |

| Water-Soluble Flux (SA) | Water-based cleaning, semi-aqueous cleaning |

| No-Clean Flux | No cleaning required |

Detailed information on the four cleaning technologies for printed circuit boards and the main factors that should be considered

Table 2 Relationship between the type of soldering flux used and the cleaning method

5.3 Other factors that should be considered

When considering which cleaning method and cleaning agent to use, you should also find the most suitable method for you based on the actual situation of the local area. Factors that need to be considered include: the original cleaning process equipment and production conditions (the site conditions of the original cleaning equipment should be used as much as possible to maintain the existing production structure and make full use of the original production conditions), safety and environmental protection requirements (non-flammable and non-explosive, harmless to the human body and no adverse effects on the environment, have occupied an increasingly important position when considering the adoption of solutions), and consideration of cleaning fees and costs (although the cleaning effect is good, the cost is too high, and it is often unacceptable if it exceeds the company's affordability, so it is usually necessary to choose a balance between cleaning effect and cost). In addition, the choice of cleaning agent and cleaning method should also be combined with the company's future development direction (such as automation level, production capacity, technology upgrade and other prospects) to make the selection forward-looking.