Ultimate PCB Cleaning Guide: Methods, Tips & Best Practices

02 Jul 2025 11:26:16 GMT

PCBASAIL

02 Jul 2025 11:26:16 GMT

PCBASAIL

Table of Contents

I. Introduction

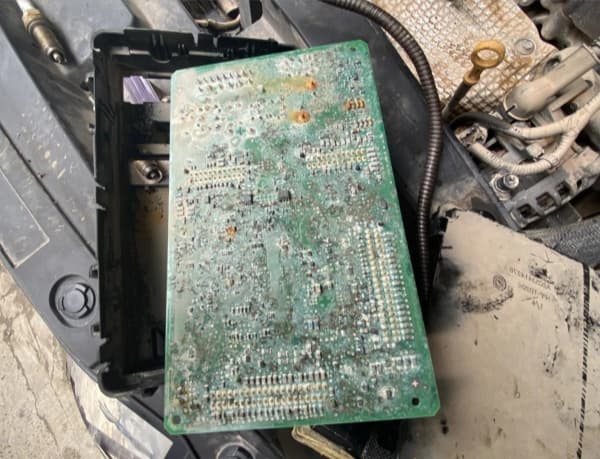

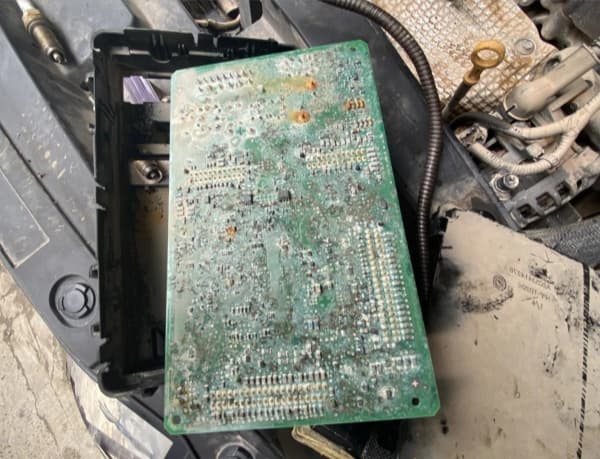

Ordinary electronics have been in use for a long time, and their circuit boards

inevitably become covered with dust. When dust accumulates excessively or the air

humidity is high, it can corrode the board or even lead to a short circuit. Whenever you

see a lot of dust on a PCB, it’s time to clean and maintain it. Even before leaving the

factory, more complex boards—like system boards, graphics cards, sound cards, network

cards, and so on—undergo cleaning. The purpose is to remove any flux residues,

fingerprints (even though everyone handling these devices wears gloves), and other

harmful substances that cling to the board during assembly.

In mass production, manufacturers use specialized cleaning fluids (commonly called “PCB

wash”) and automated washing machines. For individual users, however, it’s impractical

to operate like a board manufacturer; you only need to be careful and cautious during

the cleaning process. Cleaning a PCB isn’t difficult or scary—it’s completely doable

with the right approach.

II. Why PCBs Need Cleaning

Cleaning a PCB after manufacturing and soldering is a crucial part of the electronics

assembly process. It directly affects the device’s overall durability, reliability,

performance, and lifespan. During assembly and manufacturing, PCBs can become

contaminated with flux or solder, handling or environmental dirt—such as residues, dust,

moisture, resin or lacquer, fingerprints, or oxides. Some contaminants can even be

corrosive, damaging circuit traces and connections, leading to shorts or malfunctions

that shorten the device’s service life. Removing these kinds of debris ensures that

functional failures don’t occur over time and extends the equipment’s usable life.

When cleaning assembled PCBs, the main goal is to remove resin and flux residues left on

the board. Industries such as automotive, telecommunications, military, and aerospace

require that PCB assemblies be completely free of any potential contaminants. A

contaminant-free PCBA is essential before the next manufacturing steps—whether that’s

underfill, epoxy staking, or conformal coating. If flux residue remains on the board, it

can impair solder wetting and promote delamination. Additionally, a clean PCB simply

looks more professional.

During inspections or future troubleshooting, having a clean, tidy PCB is also

beneficial. When you clear away residual contaminants or stray solder, it’s much easier

to spot defects or potential issues.

You may encounter “no-clean” fluxes advertised as not requiring PCB cleaning after

application. However, even boards soldered with “no-clean” flux benefit from a cleaning

step—it prevents leakage currents and improves appearance. Although these fluxes are

designed to leave minimal residue, they don’t entirely eliminate the need for cleaning.

III. Main PCB Cleaning Methods

PCB cleaning typically employs different methods, each with its own advantages and

potential drawbacks. The method you choose depends on factors such as board complexity

and component density, available equipment, cost and budget, the number of boards to

clean, environmental impact, and time constraints. The main cleaning methods are:

Below is an overview of each approach.

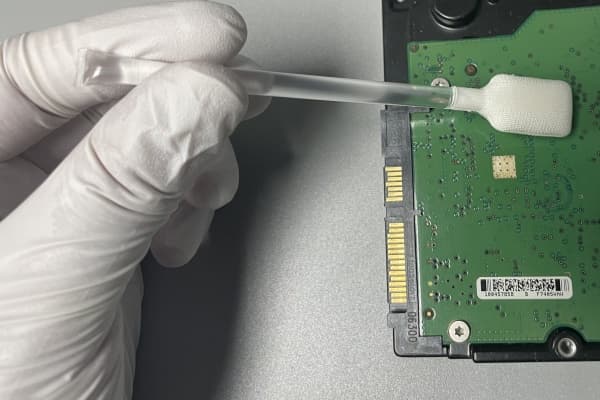

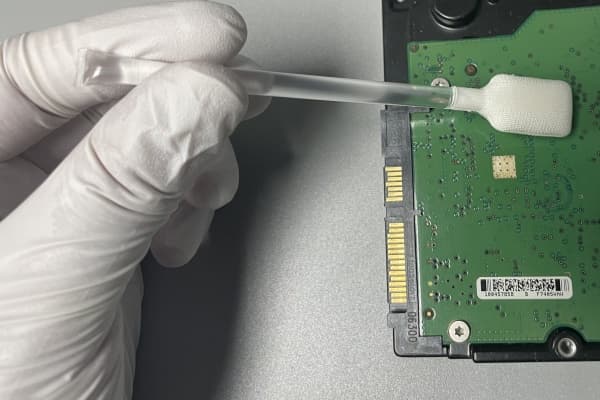

1. Manual Cleaning

One of the most common PCB cleaning methods is manual cleaning. As the name suggests,

any contamination or leftover solder can be removed by physically cleaning the board

with alcohol-based solutions and small brushes. Sometimes other tools are used alongside

brushes to physically dislodge debris.

Typical procedure:

Pros:

Cons:

Manual cleaning is best suited for prototypes, small batches, or quick maintenance when

thoroughness and speed aren’t critical.

2. Ultrasonic Cleaning

Ultrasonic cleaning uses a specialized machine designed for PCB cleaning. Like the

manual method, you first soak the board in an IPA solution to free surface dirt,

pollutants, or excess solder. Then you place it in the cleaning-fluid tank inside the

ultrasonic cleaner. The machine emits high-frequency sound waves into the liquid,

creating billions of microscopic cavitation bubbles. When these bubbles collapse, they

physically strip contaminants from the PCB—a process known as cavitation.

Pros:

Cons:

Ultrasonic cleaning is the go-to for boards that are too intricate for brushes but where

you’re willing to accept a measured risk of component stress.

3. Vapor-Phase (Vapor Degreasing) Cleaning

Also called vapor degreasing or vapor-phase cleaning, this method boils a chemical

solvent to generate vapor, which then dissolves dust and contaminants on the PCB. After

the vapor condenses back into liquid form on the cooler board, gravity returns it to the

boiling bath, completing a closed-loop cycle.

Pros:

Cons:

Vapor-phase cleaning is common in industries with stringent cleanliness standards—such

as medical or aerospace—thanks to its consistent, automated performance.

4. Deionized Water Cleaning

Deionized (DI) water is a safe, effective solution for removing water-soluble flux

residues. If you use a water-soluble flux in your leaded or lead-free solder paste, you

can rinse the PCB with DI water. Online or batch washers deliver high-temperature,

high-pressure DI water (typically around 144 °F at 45 psi) to wash and rinse assemblies,

followed by forced-air nozzles to dry the board. Ionic and resistivity tests verify

cleanliness afterward.

In some cases—particularly with eco-friendly, water-based fluxes—you can manually soak

assemblies in a water-based alcohol cleaner and then rinse with DI water. Since DI water

is the purest form of water, quality-focused contract manufacturers often standardize on

it for PCB washing.

Pros:

Cons:

IV. Selecting Your Cleaning Method

When deciding which cleaning approach to use, consider these factors:

For hobbyists or small labs, a practiced manual routine with IPA and soft brushes often

suffices. As you scale up—or if you handle mission-critical or highly dense boards—you

might invest in ultrasonic or vapor degreasing systems.

V. Best Practices & Tips

VI. Conclusion

PCB cleaning may seem like an extra chore, but it’s a vital step to ensure your

electronics perform reliably and last longer. Whether you choose manual scrubbing,

ultrasonic cavitation, vapor-phase degreasing, or water rinsing, pick the method that

matches your board’s complexity, production volume, and budget. With careful attention

to technique and best practices, you can keep your PCBs looking pristine and functioning

flawlessly for years to come.