LED Packaging PCB and DPC Ceramic PCB

Tue, 15 Jul 2025 02:37:49 GMT

PCBASAIL

Tue, 15 Jul 2025 02:37:49 GMT

PCBASAIL

1. The Importance of Thermal Conductivity in LED Packaging PCBs

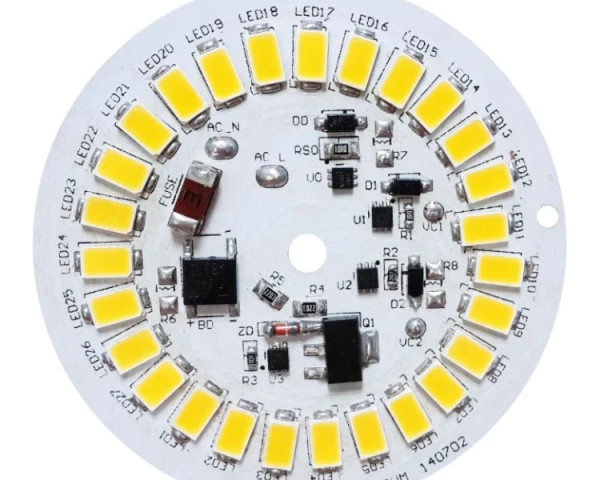

As the carrier of heat convection with air, the thermal conductivity of the power-type LED packaging PCB plays a decisive role in the heat dissipation of LEDs. DPC ceramic PCB, with its excellent performance and gradually decreasing price, shows strong competitiveness among numerous electronic packaging materials and is the development trend of power-type LED packaging in the future. With the development of science and technology and the emergence of new preparation processes, high thermal conductivity ceramic materials, as new electronic packaging PCB materials, have a very broad application prospect.

2. Increasing Power Demands Drive New Requirements for LED Packaging Materials

With the continuous increase of the input power of LED chips, the large amount of heat generated by the high dissipation power puts forward newer and higher requirements for LED packaging materials. In the LED heat dissipation channel, the packaging PCB is a key link connecting the internal and external heat dissipation paths, and it has the functions of a heat dissipation channel, circuit connection, and physical support for the chip. For high-power LED products, their packaging PCBs are required to have characteristics such as high electrical insulation, high thermal conductivity, and a thermal expansion coefficient matching that of the chip.

3. Resin-Based Packaging PCB: High Supporting Costs Make Widespread Popularization Still Difficult

Resin-based packaging PCB: High supporting costs make widespread popularization still difficultBoth EMC and SMC have high requirements for compression molding equipment. The price of a compression molding production line is about 10 million yuan, and large-scale popularization is still difficult.

The surface-mounted LED brackets that have emerged in recent years generally use high-temperature modified engineering plastic materials, taking PPA (polyphthalamide) resin as the raw material, and adding modified fillers to enhance certain physical and chemical properties of the PPA raw material, so that the PPA material is more suitable for injection molding and the use of surface-mounted LED brackets. The PPA plastic has very low thermal conductivity, and its heat dissipation mainly occurs through the metal lead frame, with limited heat dissipation capacity, and it is only suitable for the packaging of low-power LEDs.

4. Metal-Core Printed Circuit Board: Complex Manufacturing Process and Less Practical Application

The processing and manufacturing process of aluminum-based PCB is complex and costly. The thermal expansion coefficient of aluminum differs greatly from that of the chip material, so it is rarely used in practical applications. Most high-power LED packaging uses this type of PCB, and its price is between medium and high ranges.

For the currently commonly used high-power LED heat dissipation PCBs in production, the thermal conductivity of the insulating layer is extremely low. Moreover, due to the existence of the insulating layer, it cannot withstand high-temperature soldering, which limits the optimization of the packaging structure and is not conducive to LED heat dissipation.

5. Silicon-Based Packaging PCB: Facing Challenges with a Yield Rate of Less Than 60%

Silicon-based PCBs face challenges in the preparation of the insulating layer, metal layer, and vias, and the yield rate does not exceed 60%. The technology of using silicon-based materials as LED packaging PCBs has been applied in the semiconductor industry and the LED industry. Both the thermal conductivity and thermal expansion performance of silicon-based PCBs indicate that silicon is a packaging material that matches LEDs relatively well. The thermal conductivity of silicon is 140W/m·K, and when applied to LED packaging, the resulting thermal resistance is only 0.66K/W. Moreover, silicon-based materials have been widely used in semiconductor processes and related packaging fields, and the related equipment and materials involved are quite mature. Therefore, if silicon is made into LED packaging PCBs, it is easy to form mass production.

However, there are still many technical problems in LED silicon PCB packaging. For example, in terms of materials, silicon materials are prone to cracking, and there are also problems with the structural strength. In terms of structure, although silicon is an excellent heat conductor, its insulation is poor, and oxidation insulation treatment must be carried out. In addition, the metal layer needs to be prepared by a combination of sputtering and electroplating, and the conductive vias need to be formed by corrosion. Overall, the preparation of the insulating layer, metal layer, and vias all face challenges, and the yield rate is not high.

6. Ceramic Packaging PCB: Improving Heat Dissipation Efficiency to Meet the Needs of High-Power LEDs

Matching with a high thermal conductivity ceramic substrate significantly improves the heat dissipation efficiency and is the product that best suits the development needs of high-power and small-sized LEDs. Ceramic PCBs have new thermal conductive materials and new internal structures, which make up for the defects of aluminum metal PCBs and thus improve the overall heat dissipation effect of the PCB. Among the ceramic materials that can currently be used as heat dissipation PCBs, although BeO has a high thermal conductivity, its linear expansion coefficient differs greatly from that of silicon, and it is toxic during manufacturing, which limits its own application; BN has good comprehensive performance, but as a PCB material, it has no outstanding advantages and is expensive, and it is currently only under research and promotion; silicon carbide has high strength and high thermal conductivity, but its resistance and insulation withstand voltage values are low, and the bonding is unstable after metallization, which will cause changes in thermal conductivity and dielectric constant, and it is not suitable as an insulating packaging PCB material. Although the Al2O3 ceramic substrate is currently the ceramic substrate with the largest production volume and the widest application, due to its relatively high thermal expansion coefficient compared with single-crystal Si, the Al2O3 ceramic substrate is not very suitable for use in high-frequency, high-power, and very large-scale integrated circuits. The A1N crystal has a high thermal conductivity and is considered an ideal material for a new generation of semiconductor PCBs and packaging.

AlN ceramic PCBs have been widely studied and gradually developed since the 1990s and are currently widely regarded as an electronic ceramic packaging material with great development prospects. The heat dissipation efficiency of AlN ceramic PCBs is more than 7 times that of Al2O3. The application of AlN ceramic PCBs in the heat dissipation of high-power LEDs has significant benefits, which greatly improves the service life of LEDs.

The direct bonded copper ceramic board (DBC) developed based on the packaging technology on the board is also a ceramic PCB with excellent thermal conductivity. No binder is used in the preparation process of DBC, so it has good thermal conductivity, high strength, strong insulation, and a thermal expansion coefficient that matches semiconductor materials such as Si. However, ceramic PCBs have low reactivity with metal materials and poor wettability, and it is quite difficult to implement metallization. It is not easy to solve the problem of micro-pores generated between Al2O3 and the copper plate, which makes mass production and the yield rate of this product face great challenges and remains the focus of research by scientific researchers at home and abroad. Currently, only a few companies led by Silitone in China can achieve mass production.

7. DPC Ceramic PCB: A Revolutionary Solution for High-Power LED Packaging

DPC ceramic PCB, also known as direct copper plating ceramic board, DPC products have the characteristics of high circuit precision and high surface flatness, and are very suitable for LED flip-chip/eutectic processes. Matching with a high thermal conductivity ceramic substrate significantly improves the heat dissipation efficiency and is a revolutionary product that best suits the development needs of high-power and small-sized LEDs.