How PCBASAIL Assembly PCB Board Step By Step

08 Apr 2025 14:41:43 GMT

PCBASAIL

08 Apr 2025 14:41:43 GMT

PCBASAIL

Table of Contents

With the continuous development of

electronic technology, electronic products have been widely used in various fields of life.

However, PCB production and assembly is an important part of product production. We found that

many customers, whether they are engineers entering the industry or experienced professionals,

do not fully understand the process of PCB production and assembly. In order to let customers

better understand how we transform their PCB design data into the final high-quality PCBA board,

I will share entire production process from raw material preparation to PCB patch assembly to

show our professional production technology and how we ensure the reliability and performance of

each PCB board we produce.

What Files We Need To Assembly PCB Board?

In the PCB production and assembly process, in order to ensure that we can correctly produce the PCBA board we need, we must prepare all the files required for production. These files include PCB files, drilling files, BOM (Bill of Materials), assembly drawings and other requirements, etc.PCB Files

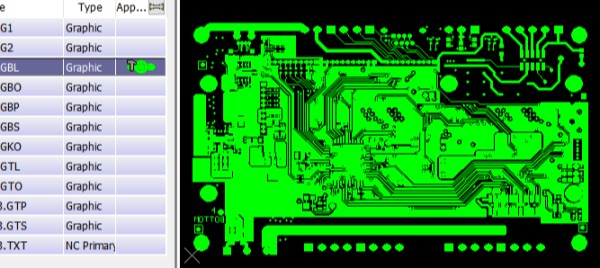

The PCB tool we commonly use include Altium Designer: .PcbDoc, KiCad: .kicad_pcb, Eagle: .brd, and Gerber files format (RS-274X) file is the main file for PCB production, which contains the graphic information of each layer of the PCB.- Top Layer and Bottom Layer

- Inner layers

- Solder Mask

- Silkscreen

- Drill File

- Board Outline

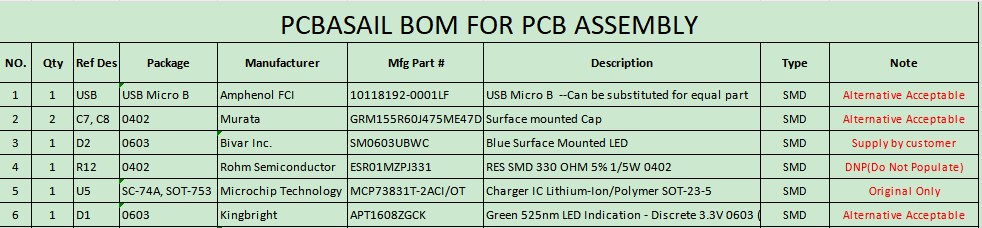

BOM List

BOM (Bill of Materials): BOM is an indispensable file for component procurement and assembly, mainly in Excel or CSV file format. BOM needs to contain detailed information of all components required for PCB- Part Number

- Description

- Package Type

- Quantity

- Reference Designator

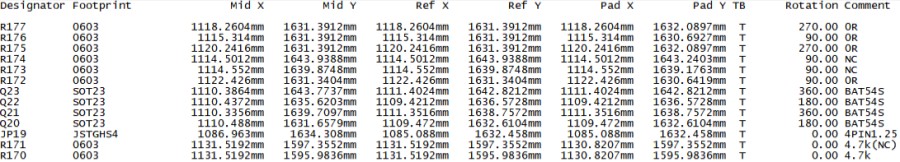

3,Pick and Place Files

The coordinate file is preferably in the text file CSV or TXT format, which is used to help SMT accurately mount BOM electronic components. It contains the component designator, X coordinate, Y coordinate, component installation direction, component package, and whether the component is located on the top or bottom of the PCB.

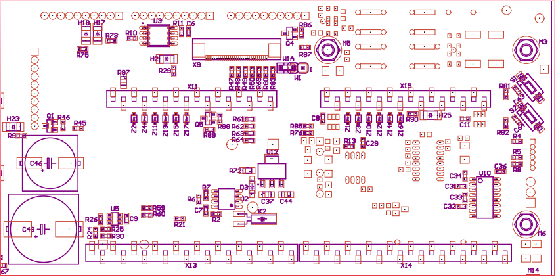

4,Assembly drawings

Assembly Drawing: Although it is not an essential document, a detailed assembly drawing can help us check whether the components are correctly mounted and avoid assembly errors. It is mainly in the form of PDF or DXF files and contains the following information- Reference Designator

- Polarity Markings

- Install Orientation

5,Firmware programming and function test

We hope to help customers test and burn. Customers only need to provide the tools and methods required for firmware and burning test. Our engineers will burn and test all PCB boards before shipment to ensure that the PCB boards can operate normally. Potential problems can be found through testing, reducing rework and repair costs, and avoiding delays or failures of customer projects due to PCB problems.What Machines we use for PCB assembly

In the whole PCB assembly process, we need to use a lot of equipment, so what equipment is our production workshop equipped with?- Solder Paste Printer

- Solder Paste Detection Instrument

- Pick and Place Machine

- Reflow Oven

- First Article Tester

- AOI Equipment (Automated Optical Inspection)

- X-Ray Inspection Equipment (X-Ray Inspection Machine)

- Wave Soldering

- Dry Ice Cleaning Machine