FPC flexible board, namely Flexible Printed Circuit Board, is a type of printed circuit

board made from flexible substrates, often referred to as soft circuit boards or

flexible circuit boards. FPC flexible boards have now been widely used in modern

electronic products, as they are thin, lightweight, and bendable, and can be processed

into any shape and size, complementing FR-4 PCB rigid boards. However, due to

differences from rigid PCB boards, there are special considerations in design. This

article focuses on 8 key design points of FPC:

Drilling, board frame, circuit, solder mask, and text design for flexible boards are

similar to those for PCBs, except that stiffener layers need to be added on the back of

components and at interface positions. However, there are also special considerations,

introduced as follows:

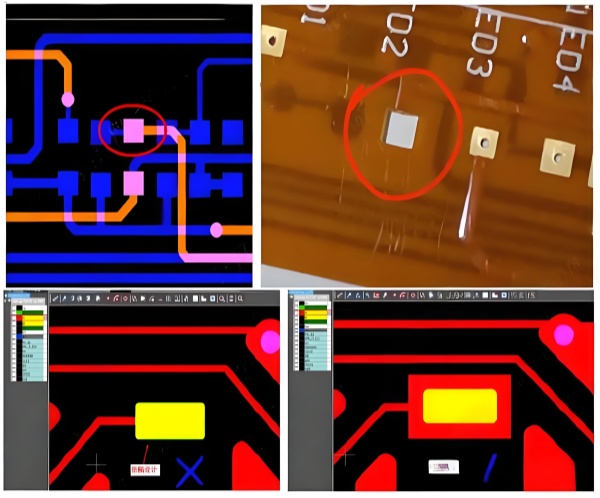

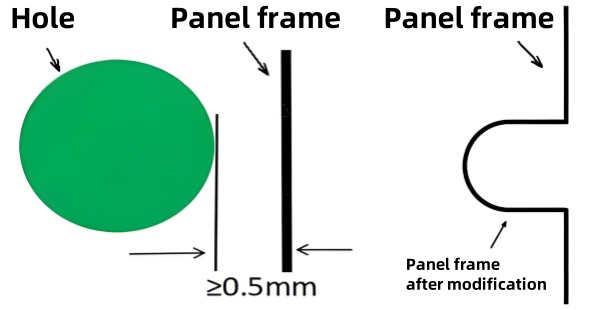

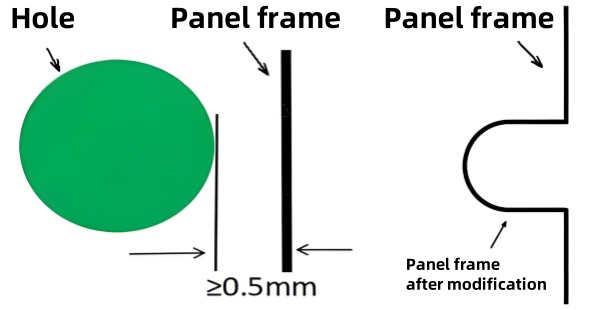

(1) The minimum distance from a through-hole to the board frame line is 0.5mm. If less

than 0.5mm, it should be changed to a U-shaped hole (the hole is connected to the board

frame).

(2) The distance from a via

to the solder mask opening should be at least 0.2mm; otherwise, copper may be exposed at

the hole edge.

(3) It is not

recommended to design vias-in-pad for FPC. FPC cannot perform resin plugging, and

vias-in-pad may cause solder leakage.

(1) Oxidation of large copper surfaces: Due to the design of large

copper surfaces, air is difficult to evacuate during film lamination. Moisture in the

air reacts with the copper surface under high temperature and pressure to cause

oxidation, resulting in poor appearance (functionality is not affected). To avoid this,

design grid copper cladding or add solder mask openings on large copper surfaces.

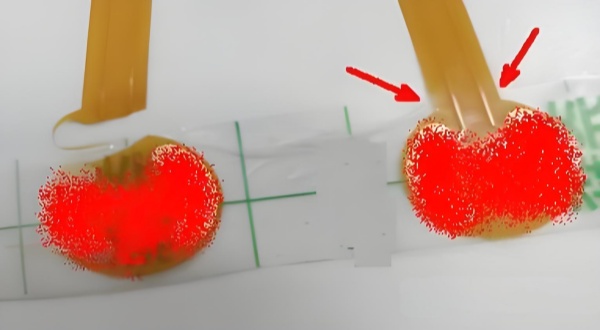

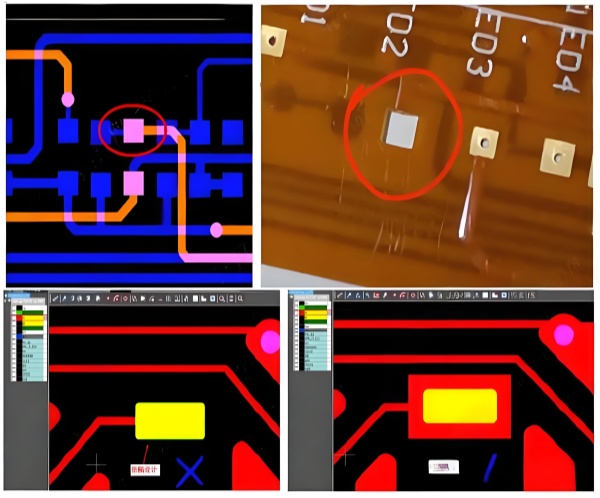

(2) Avoid independent

solder pads: As shown in the figure, circuit solder pads that are independent

and overlapping on both sides are prone to detachment (since the intermediate substrate

of FPC is only 25μm). It is recommended to add copper cladding, connect the four corners

of the pads to the copper cladding with connecting lines, and stagger the upper and

lower pads to increase bonding strength.

(3)

Pad detachment: Connector seat pads are relatively independent and

prone to detachment; use pressed PAD design.

(4) Avoid large areas of exposed

copper, as this may cause wrinkles.

(5) FPC uses coverlay as the

solder mask layer. The coverlay needs pre-opening and bonding. There should be a 0.2mm

spacing between the solder pad and the trace, and the solder mask bridge should be at

least 0.5mm (i.e., the spacing between two solder pads should be at least 0.5mm).

Otherwise, open a full window and accept exposed traces.

(6)

Tearing at

corners: Sparse cable traces make corners prone to tearing. Add anti-tear

copper strips on the board edge or grid copper on the back.

(7) The circuit grid is preferably laid at a 45-degree angle for better signal

transmission. The recommended line width and spacing are 0.2/0.2mm.

(1) For pluggable fingers: High-temperature carbonization at the board edge during laser

cutting may cause micro-shorts between gold fingers. The gold fingers need to be

recessed by 0.2mm (generally uniformly recessed; special requirements should be

specified).

(2) For soldering

fingers: Vias on the in-board solder pads should not be arranged in a single row to

prevent stress concentration and breakage.

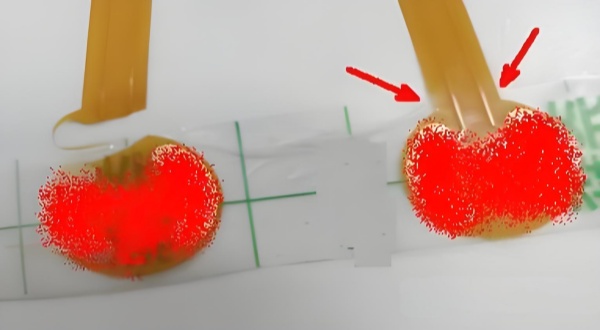

(3) The upper and lower coverlays

of soldering fingers should be staggered by more than 0.3mm to prevent breakage.

(4) Soldering fingers are

recommended to have a solder mask film pressing PAD effect (i.e., extend the solder pad

so that the coverlay presses the pad by more than 0.3mm).

(5) Solder mask opening for gold

fingers: The opening is recommended to press the pad by more than 0.3mm to prevent

disconnection between the gold finger PAD and the connection.

(6) If hollow boards are not

supported, reverse fingers need to add pads and vias to achieve layer change.

(7) Since FPC solder mask film

cannot form solder mask bridges like green oil, IC-type pads should have no extra copper

cladding (unreasonable design may cause soldering short circuits due to larger pads and

reduced spacing).

(8) Gold finger

pads should be independent; copper cladding or traces on finger pads will be exposed

after solder mask opening.

(9) The

default tolerance for gold finger outline is ±0.1mm; ±0.05mm requires confirmation when

placing an order.

(1) FPC connector seats are prone to detachment; use pressed PAD design.

(2) Bridging is required in the

middle of the IC to retain the intermediate solder mask.

(3) Gold finger pads must have

solder mask openings; otherwise, they cannot conduct with the connector.

(4) Soldermask is used as the

default solder mask layer; ensure the correctness of the solder mask layer.

(5) To prevent via copper from

breaking during bending, FPC vias are generally defaulted to be oil-covered; opening

requires notation when placing an order.

(6) Test points designed as via

attributes may not be transferred correctly; avoid via attributes or set separate

openings.

(7) Large exposed copper

gold surfaces on the edge of double-sided boards may cause edge blackening; add a circle

of coverlay on the board edge.

(1) If there are character silk screens on the stiffener, select "silk screen on

stiffener" when placing an order to prevent process errors.

(2) Instruction text should not be

designed inside the board to avoid issues in subsequent processes.

(1) For boards with steel stiffeners: The minimum spacing between boards is recommended

to be 3mm, the slot width is 0.5mm, and the connection point width is 1mm (one added

every 15mm or so). Note when placing an order: Separate each piece with paper, and ship

with cardboard clamping top and bottom.

(2) Panelization connection

positions on gold fingers will cause uneven front ends of gold fingers.

(3) Too few connection points

cause boards to fall off easily; each PCS should have at least 2 connection points

(width 0.8mm), with more for larger boards.

(4) For small boards without SMT:

Each PCS only needs 2 connection points of 0.3mm for easy hand-breaking.

(5) Low panelization utilization

leads to high quotations; optimal panel widths are 119mm or 240/250mm; third-party

panelization is recommended.

(6)

Boards smaller than 20×20mm may be sucked away by laser dust suction; deliver panels or

depanelize after production.

Stiffening of flexible circuit boards refers to adding rigid materials to local areas of

FPC to facilitate assembly. PI stiffeners are suitable for gold finger pluggable

products; FR4 for lower-end products; steel sheets (good flatness, no deformation) for

chip mounting products. See details in the Stiffener Specification Diagram.

(1) Avoid steel sheets as stiffeners for component insertion holes (risk of short

circuits), with Hall elements (weak magnetism), or for pluggable gold fingers.

(2) For pluggable gold fingers,

note total thickness requirements (specified in connector specifications); PI stiffener

thickness is not directly calculated by subtracting FPC board thickness from total

thickness.

(3) Stiffener opening

design: Avoid underlying component holes or pads (customer design is preferred; default

avoids pads by 0.3mm). Stiffeners with remaining width <2mm after cutting are

omitted.

(4) The height of the gold

finger stiffener should be at least 1.0mm longer than the gold finger pads to prevent

breakage.

(5) Electromagnetic film

with conductive sides: Cancel design if the lower film is not a single network.

(6) For electromagnetic film

grounding resistance requirements: Customer designs independent grounding solder mask

openings (default adds >1.0mm windows randomly). Note: Ungrounded electromagnetic

film may cause signal problems; prototyping and verification are necessary.

(7) Attaching steel sheets to

solder pads causes short circuits.

(8)

Stiffener width: FR4 stiffeners with width <5mm are prone to breakage and

carbonization; change to PI or steel stiffeners. Adhesive backing minimum width >3mm.

(9) No stiffeners or adhesive

backing around chip mounting pads (prevents solder paste printing); chip mounting should

precede stiffener/adhesive backing attachment if necessary.

The board thickness includes the coverlay, copper thickness, and substrate PI thickness.

Boards with copper-free areas or no coverlay have correspondingly reduced thickness; pay

special attention during design.

03 Jun 2025 15:48:06 GMT

PCBASAIL

03 Jun 2025 15:48:06 GMT

PCBASAIL